Mining machinery, crusher, mining plant, mobile plant, batching plant, vibrating screen, more ...

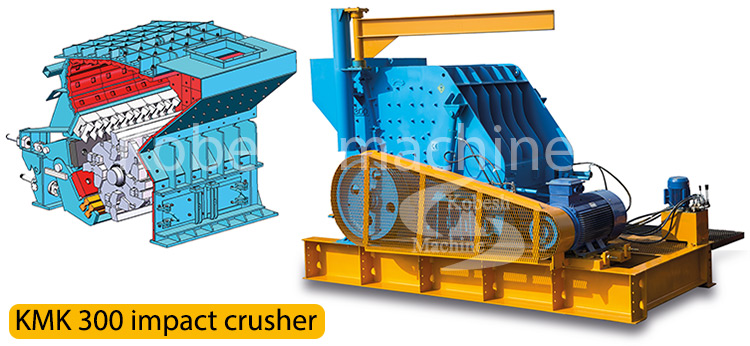

Kobesh KMK series crushers, which belongs to our Impact crushers group with adjustable breakers are very safe and efficient crushers for medium hard and hard stones (limestone, dolomite and basalt etc..) for the production of asphalt and concrete aggregates. Large feed opening, cubical products, high reduction ratio, high capacity, low investment and operating costs are some of the features which make these crushers ideal as secondary crushers in crushing & screening plants.

Crusher is made up of easily detachable three main parts; Rotor, Fixed bottom assembly which carries rotor and top assembly. Upper assembly can easily be opened by a hydraulic mechanism with two cylinders and reveals the rotor and inner parts. Assembly and dismantling operations are very simplified.

Rotor hammers impact incoming stones to the crushing plates in Crushing Zone I and first crushing stage is completed there.

Even materials, which are difficult to reduce, can be easily crushed by high pressure and crushing power produced In Zone I (Primary Stage).

When the material is reduced sufficiently it passes to Crushing Zone II, otherwise it is again send to Zone I until it is sufficiently reduced. (Secondary Stage) In Zone II, the material passes through another crushing stage and is reduced further.

The reduced material passes to Zone III and final crushing occurs here (Tertiary Stage). At the end, the material is reduced to its minimum grades.

1. Primary Crushing Chamber

The Feed Material passes through the inlet opening into the primary crushing chamber. It is held by the impact bars and thrown towards the crushing plates.

2. Grinding Carriage-Secondary Crushing All reduced material from the first stage reach the secondary crushing zone. Insufficiently crushed material remains in the primary crushing zone. In this stage, the material again reduced in required size.

3. Grinding Rails-Tertiary Crushing After the second stage of reduction, the material flows into the third crushing stage where it is subjected to tertiary reduction.

4. Rotor

Rotor assembly has very robust design and fabricated rigidly.

Rotor shaft is composed of forged and heat-treated high quality steel. It is equipped with drive journals on both sides to allow installation of V-belt. The bearings are heavy-duty self aligning roller bearings. Impact bars have an extremely high resistance to rupture. The self-centering impact bars inserted laterally into the rotor and tightened by special wedges.

5.-6. Housing

The housing is designed in robust welded construction and consists of the lower part of the machine and a stationary and movable upper part of the housing. After loosening the screws of the hinged element the movable upper part of the housing can be opened hydraulically.

7. Grinding Carriage Adjustment Assembly With the help of mechanical adjusting spindles the complete grinding carriage will be adjusted infinitely to set the gap width between the grinding plate and rotor impact bar.

8. Grinding Rails Adjustment Assembly The gap width between the grinding plate and rotor impact bar is also infinitely set with mechanical adjusting spindle.

DMK 03- KMK300 IMPACT CRUSHER

KOBESH SBM-AT KMK200 IMPACT CRUSHER

РОТОРНЫЕ ДРОБИЛКИ 300 TON - HOUR

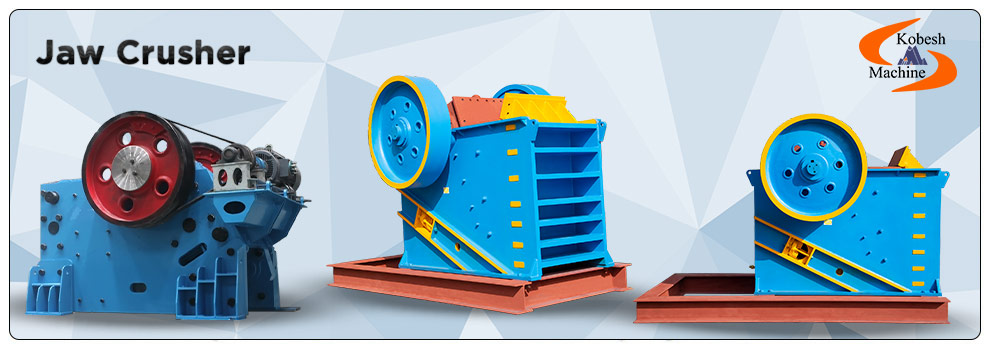

crusher plant

crusher plant