vibrating screen

Advanced Crushing Solutions by Kobesh Machine

With decades of continuous experience in the design and manufacturing of crushing equipment, kobesh machine is recognized as a leading manufacturer in the mining and asphalt industries.

Having successfully installed thousands of crushing machines worldwide, kobesh machine has built a strong reputation for reliability, performance, and engineering excellence across mining, road construction, and asphalt plant projects.

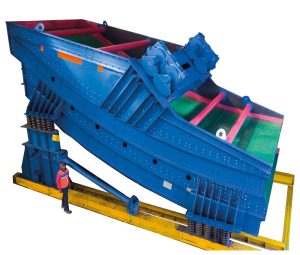

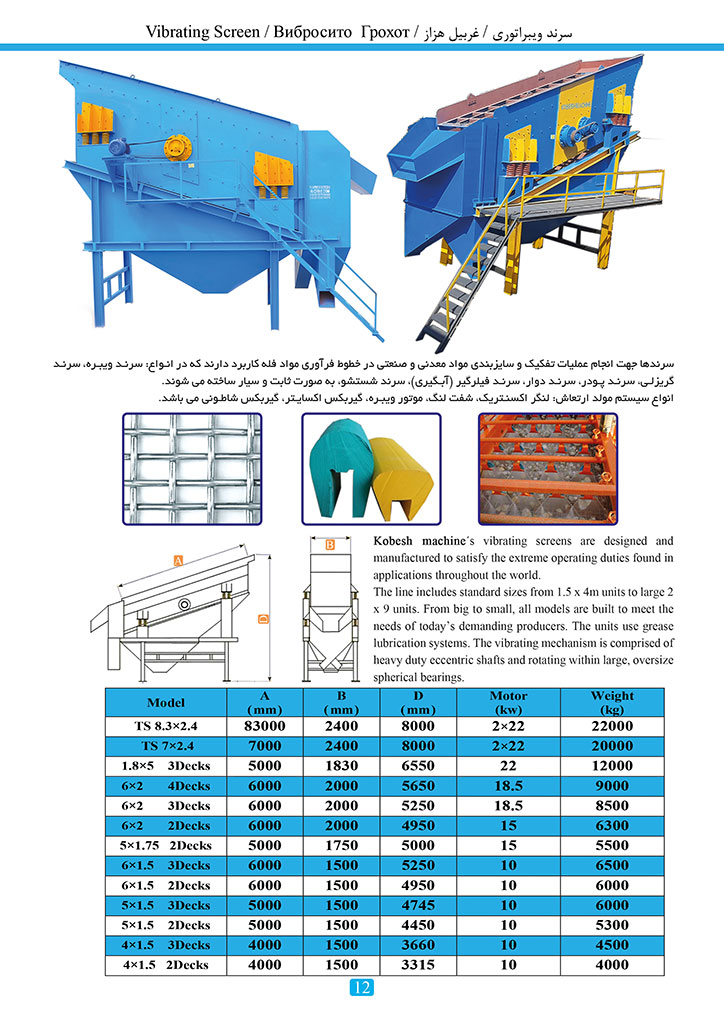

Vibrating Screen

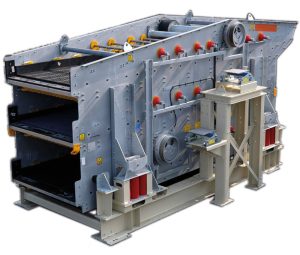

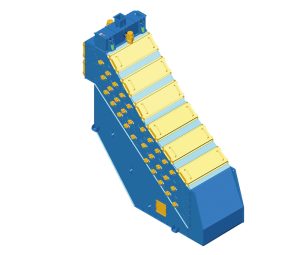

The Vibrating Screen is a key piece of equipment in crushing and mineral processing lines, designed for screening, grading, and separation of materials in various capacities. It is widely used in mining, sand and gravel plants, iron ore processing, and bulk material handling industries.

Structural Features

Heavy-duty steel structure with industrial design

Available in 2-deck, 3-deck, and 4-deck configurations

Equipped with heavy-duty eccentric shafts

Large spherical bearings designed for high load capacity

Suitable for continuous and severe operating conditions

Ability to use single or dual electric motors depending on model

Operating Mechanism Description

The vibration mechanism of the screen is generated by eccentric rotating shafts driven by electric motors. As the shafts rotate, a controlled and uniform vibration is transmitted across the screening surface, allowing the material to move forward and be separated according to particle size.

This system is designed for heavy-duty continuous operation and uses a grease lubrication system.

Manufacturing Specifications

Vibration system: Eccentric shaft mechanism

Lubrication system: Grease lubrication

Bearing type: Heavy-duty spherical bearings

Drive system: Single or dual motor (model-dependent)

Size range: From small to large industrial units

Application: Screening, grading, washing, and separation of mineral materials

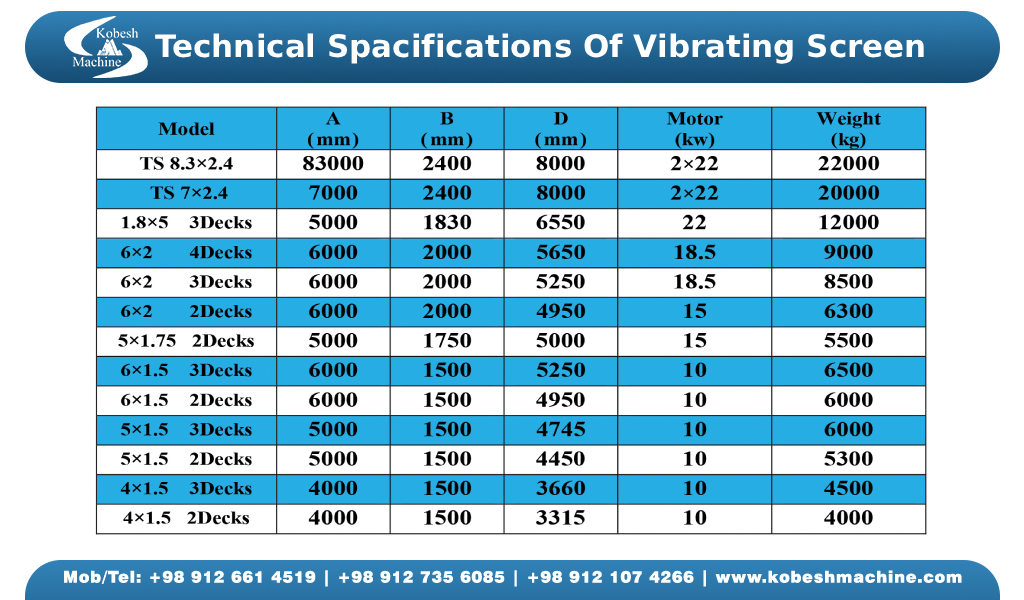

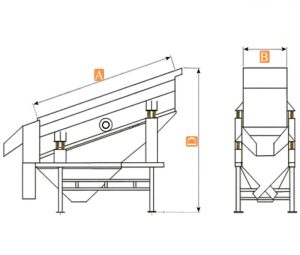

Technical Table Analysis

The vibrating screens presented in this catalog cover a wide range of dimensions, weights, and motor power ratings. Larger models such as TS 8.3×2.4, weighing 22 tons and powered by two 22 kW motors, are suitable for heavy-duty, high-capacity crushing and screening lines. Smaller models such as the 4×1.5 two-deck screen, weighing 4 tons with a 10 kW motor, provide an economical solution for lighter screening applications. Increasing the number of decks improves screening accuracy and separation efficiency.

Spare parts and components of the Vibrating Screen

Main frame and structural body

Eccentric shaft

Electric motors

Spherical bearings

Screen meshes (wire or polyurethane)

Lubrication system

Springs and vibration isolators

Support structure and base frame

🔧 We are also a manufacturer of spare parts

All consumable and spare parts such as shafts, bearings, screen meshes, springs, motors, and mechanical components are manufactured and supplied by us.

📞 For spare parts supply and technical consultation, please contact us.

Projects

The vibrating screens presented in this catalog have been used in numerous stone quarries, sand and gravel plants, and both mobile and stationary crushing lines, demonstrating reliable and stable performance under different operating conditions.

Kobesh Machine stands as a symbol of durability, high productivity, and secure industrial investment.

Contact Us

To receive tailored technical consultation, review high-capacity models, and select the most suitable solution aligned with the scale of your investment, please contact our executive team directly:

Sales Manager: +989126614519 Mr. Alipour

R&D and Engineering Manager: +989123657790 Mr. Alipour (24/7)

Our specialists are ready to support you from technical evaluation to final equipment selection for large-scale and international projects.

Take control of crushing power—secure the future of your project.