Kobesh Machine | Engineering Solutions for Mining & Asphalt Plants

At Kobesh Machine, we specialize in the design, manufacturing, and supply of mining machinery and asphalt plant equipment, delivering reliable and high-performance solutions for industrial projects. By combining technical expertise with hands-on industry experience, we produce durable machines that meet the demanding requirements of mining operations, crushing lines, and road construction projects.

In addition to manufacturing equipment such as crushers, feeders, screens, and asphalt plant systems, we also produce and supply spare parts and provide dependable technical support to our clients. Our strong presence in numerous mining, sand and gravel, asphalt, and cement projects reflects our commitment to quality, operational efficiency, and long-term customer satisfaction.

Vibrating Feeder

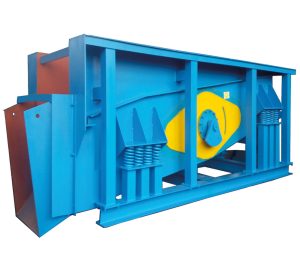

The Vibrating Feeder is one of the key machines used in crushing and screening lines for mineral processing. It is designed to provide uniform and controlled feeding of stone and mineral materials to crushers and screens. With its industrial design and adjustable feeding rate, this machine significantly improves the overall efficiency of processing plants.

Key Features of Vibrating Feeder

Heavy-duty steel frame suitable for mining applications

Large feeding hopper for high-volume material intake

Spring and vibration system for smooth and uniform feeding

Suitable for installation in crushing and screening lines

Industrial design for continuous and demanding operation

The Vibrating Feeder presented in this catalog is a powerful and reliable machine suitable for mineral processing lines, sand and gravel plants, and stone quarries. Thanks to its robust construction and engineered vibration system, it ensures consistent and uninterrupted material flow at various capacities.

The adjustable feeding speed, durable spring system, and appropriately sized motor make this feeder ideal for continuous heavy-duty operation. Available in multiple models with different capacities, the vibrating feeder can handle a wide range of feed sizes while preventing blockages and overloads in downstream equipment.

Operating Mechanism Description

The operating mechanism of the vibrating feeder is based on controlled vibration. This vibration causes the material to move gradually from the hopper toward the discharge outlet. By adjusting the vibration speed, the feeding rate to crushers or screens can be precisely controlled. This controlled feeding prevents sudden overloads and contributes to longer service life and improved performance of downstream equipment.

Construction Specifications

Machine Type: Vibrating Feeder

Application: Feeding mineral materials, stone, sand, and gravel

Feeding System: Vibratory motion

Speed Control: Available

Suitable for crushing and screening production lines

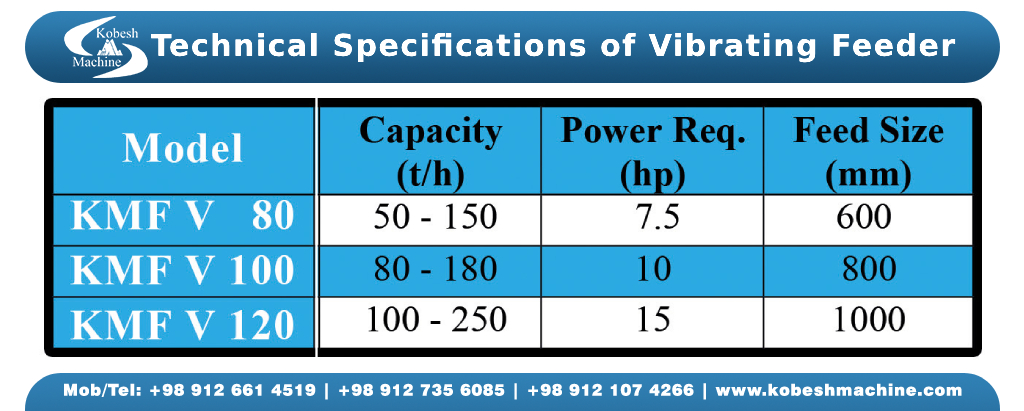

Technical Data Description (Based on Table)

The vibrating feeders are available in three models: KMF V 80, KMF V 100, and KMF V 120, each designed for different production capacities and feed sizes. The KMF V 80 model offers a capacity of 50 to 150 tons per hour with a 7.5 horsepower motor and is suitable for feed sizes up to 600 mm. The KMF V 100 model provides a higher capacity ranging from 80 to 180 tons per hour, powered by a 10 horsepower motor, and can handle feed sizes up to 800 mm. The KMF V 120 model is designed for heavy-duty applications, offering a capacity of 100 to 250 tons per hour with a 15 horsepower motor and accommodating feed sizes up to 1000 mm, making it ideal for high-capacity crushing lines.

Spare parts and components Of Vibrating Feeder

Feed Hopper: Receives and directs raw material into the feeder

Main Frame and Body: Supports loads and withstands continuous vibration

Vibration and Spring System: Ensures uniform material movement

Electric Motor: Provides the required vibration power

Discharge Outlet: Delivers controlled material flow to downstream equipment

🔧 Spare Parts Manufacturing

We are a manufacturer of vibrating feeder components. All spare parts, including body parts, vibration systems, springs, and other mechanical components, are produced and supplied by our company. For spare parts supply and technical consultation, please contact us.

Projects

These vibrating feeders have been successfully used in various mining projects, sand and gravel plants, and stone crushing lines, delivering stable and reliable performance under industrial working conditions.

Kobesh Machine stands as a symbol of durability, high productivity, and secure industrial investment.

Contact Us

To receive tailored technical consultation, review high-capacity models, and select the most suitable solution aligned with the scale of your investment, please contact our executive team directly:

Sales Manager: +989126614519 Mr. Alipour

R&D and Engineering Manager: +989123657790 Mr. Alipour (24/7)

Our specialists are ready to support you from technical evaluation to final equipment selection for large-scale and international projects.

Take control of crushing power—secure the future of your project.