Advanced Crushing Solutions by Kobesh Machine

With decades of continuous experience in the design and manufacturing of crushing equipment, kobesh machine is recognized as a leading manufacturer in the mining and asphalt industries.

Having successfully installed thousands of crushing machines worldwide, kobesh machine has built a strong reputation for reliability, performance, and engineering excellence across mining, road construction, and asphalt plant projects.

Hammer mill

The Hammer mill (Hammer Crusher) is a key piece of crushing machinery that uses the impact of high-speed hammers to break materials into finer particles. This device is particularly suited for secondary and fine crushing, as well as for producing micronized powders and manufactured sand. Due to its simple structure, high crushing ratio, low energy consumption, and reliability, the Hammermill is an ideal choice for various industries, including cement production, coke processing, organic fertilizer manufacturing, stone crushing, and mineral processing.

Structural Features hammer mill

- Compact and Robust Design: The machine’s body is constructed from durable steel to withstand heavy impacts.

- High-Speed Rotor with Steel Hammers: The heart of the Hammermill is a rotor that spins at high speed, carrying a set of robust steel hammers.

- Impact Mechanism: The direct collision of hammers with the material is the primary crushing action.

- Suitable for Secondary and Fine Crushing: Ideal for further reducing material size after initial crushing stages.

- Capacity for Producing Sand and Powder: Capable of transforming materials into fine and uniform particle sizes.

- Simplicity in Structure and Maintenance: Relatively easy access to components for repair and replacement.

- Optimized Energy Consumption: Designed for maximum efficiency with minimal energy usage.

- High Crushing Ratio: Ability to significantly reduce the size of input particles.

hummer mill

Mechanism of Operation The Hammermill’s operation is based on impact and attrition. Raw materials enter the crushing chamber through the feed inlet. The rotor, spinning at high speed, drives the hammers mounted on it. These hammers strike the incoming material, breaking it into smaller pieces. The crushed materials are then thrown towards the internal walls and against other hammers, leading to further fragmentation and eventual pulverization. Finer particles pass through the screen at the bottom of the machine and are discharged as the final product.

Build Specifications

- Body Material: High-strength industrial steel.

- Hammer Material: Special alloy steel, resistant to wear and impact.

- Rotor Material: Robust steel.

- Screen/Grate: Perforated plates made of strong steel.

- Motor: Standard industrial electric motors.

- Bearings: High-quality industrial bearings.

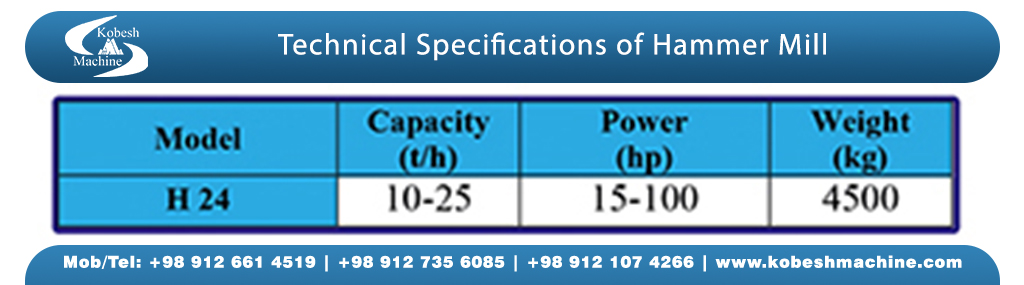

Technical Specifications Table hammer mill

- Model: H 24

- Capacity (t/h): 10-25

- Power (hp): 15-100

- Weight (kg): 4500

- Max. Feed Size (mm): (Not specified in the photo text, but the H24 model is typically for smaller materials)

- Product Output Size (mm): 0-5 (According to the second photo, which indicates the H24 model for powder production)

Component Descriptions hammer mill

- Hammers: The primary crushing components that strike materials at high speed. Made from highly wear-resistant alloy steels.

- Rotor: The main shaft onto which the hammers are mounted and which rotates at high speed.

- Crushing Chamber (Body): The main housing of the machine where crushing takes place.

- Screen/Grate (Output Screen): A perforated plate at the bottom that controls the size of the output particles.

- Feed Inlet: The point where raw materials enter the machine.

- Motor: The power source for rotating the rotor.

- Drive System: Includes belts and pulleys for transferring power from the motor to the rotor.

We are a parts manufacturer, contact us for parts procurement As a specialized manufacturer of Hammermill parts, we offer a range of durable, wear-and-impact-resistant hammers, high-precision screens, and components for the body and rotor, utilizing the best raw materials and advanced technology. The quality of spare parts guarantees the operational lifespan and efficiency of your machine. Contact us for price inquiries and to order your required parts.

Projects

- Description: Our Hammermills have been utilized in various projects for producing micronized powder materials, manufactured sand, and processing various minerals such as gypsum, limestone, and coal. They are also employed in organic fertilizer production lines and forging applications. Their reliability, high efficiency in fine crushing, and suitable lifespan have made these machines a popular choice in related industries.

Kobesh Machine stands as a symbol of durability, high productivity, and secure industrial investment.

Contact Us

To receive tailored technical consultation, review high-capacity models, and select the most suitable solution aligned with the scale of your investment, please contact our executive team directly:

Sales Manager: +98 912 661 4519 — Alipour

R&D and Engineering Manager: +98 912 365 7790 — Alipour

Our specialists are ready to support you from technical evaluation to final equipment selection for large-scale and international projects.

Take control of crushing power—secure the future of your project.