Advanced Crushing Solutions by Kobesh Machine

With decades of continuous experience in the design and manufacturing of crushing equipment, kobesh machine is recognized as a leading manufacturer in the mining and asphalt industries.

Having successfully installed thousands of crushing machines worldwide, kobesh machine has built a strong reputation for reliability, performance, and engineering excellence across mining, road construction, and asphalt plant projects.

Concrete Batching Plant

Product Overview Our Concrete Batching Plant is a complete solution for professional concrete mixing, featuring standard components and an advanced control system. It is designed to simplify workflows on large construction projects. The following sections describe the product in detail.

Structural features Concrete Batching Plant

- Cement Silo with capacity configurable per project

- Mixers: Drum mixer or twin shaft mixer or pan mixer (type selected by application)

- Electronic weighing and aggregate batching system

- Pneumatic compressor

- Belt conveyor and Screw conveyor

- Control cabin

- Water pump and water meter

- Aggregate feeders

Concrete Batching Plant

Brief product description The plant is designed to handle cement storage, multiple mixer types, electronic weighing and aggregate batching, pneumatic systems, conveyors, a control cabin, water management, and aggregate feeders. It is configurable to meet a range of project requirements.

How it works (mechanism) Dry materials and water are fed into the cement silo and other ingredients. The electronic weighing system measures each component precisely and sends the data to the mixer. In the mixer, exact mix ratios are achieved, and the final concrete is directed to the output unit, trucks, or a concrete pump. All sections are managed from the control cabin, enabling monitoring, synchronization, and data logging for project efficiency.

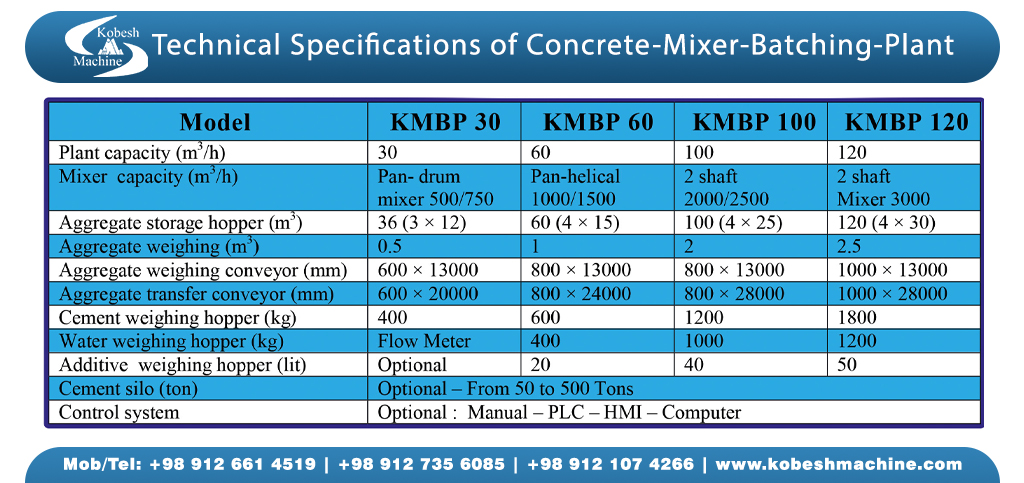

Table Below is a concise extraction of the table’s key items, presented in paragraph form: The table covers Cement Silo capacity and dimensions per project, Mixer type options (Drum / Twin Shaft / Pan), Electronic weighing and aggregate batching system, Pneumatic compressor, Belt conveyor, Screw conveyor, Control cabin, Water pump and water meter, and Aggregate feeders, highlighting their availability and configurable nature.

Build specifications Concrete Batching Plant

- Robust metal frame with user-friendly design

- Compatibility with different mixers (Drum / Twin Shaft / Pan)

- Electronic control system with adjustable settings and easy maintenance

- Configurable options for precise measurement of materials and water

- Maintainable design with solid after-sales support

Technical specifications table (summary)

- Cement Silo: capacity and dimensions per project

- Mixer type: Drum / Twin Shaft / Pan

- Electronic weighing and aggregate batching system

- Pneumatic compressor

- Belt conveyor

- Screw conveyor

- Control cabin

- Water pump & water meter

- Aggregate feeders

Component introductions

- Cement Silo: secure storage for cement with easy access and moisture protection

- Mixers (Drum / Twin Shaft / Pan): high-efficiency mixers for thorough material blending

- Electronic weighing and aggregate batching system: precise weighing and batching according to set ratios

- Pneumatic compressor: air source for pneumatic components and smart systems

- Belt conveyor: belt conveyor for fast, long-distance material transport

- Screw conveyor: screw conveyor for continuous material transfer

- Control cabin: control room with displays, controls, and safety features

- Water pump & water meter: water management for accurate water ratio

- Aggregate feeders: precise feeders to regulate input materials

We are a manufacturer of parts and components for Concrete Batching Plants. For parts procurement, please contact our sales and after-sales team to get the best solution tailored to your project.

Projects

- Description: Implemented projects include equipping concrete plants, large construction sites, and infrastructure projects using advanced batching systems; covers design, commissioning, operator training, and after-sales service.

Kobesh Machine stands as a symbol of durability, high productivity, and secure industrial investment.

Contact Us

To receive tailored technical consultation, review high-capacity models, and select the most suitable solution aligned with the scale of your investment, please contact our executive team directly:

Sales Manager: +989126614519 Mr. Alipour

R&D and Engineering Manager: +989123657790 Mr. Alipour (24/7)

Our specialists are ready to support you from technical evaluation to final equipment selection for large-scale and international projects.

Take control of crushing power—secure the future of your project.