Advanced Crushing Solutions by Kobesh Machine

With decades of continuous experience in the design and manufacturing of crushing equipment, kobesh machine is recognized as a leading manufacturer in the mining and asphalt industries.

Having successfully installed thousands of crushing machines worldwide, kobesh machine has built a strong reputation for reliability, performance, and engineering excellence across mining, road construction, and asphalt plant projects.

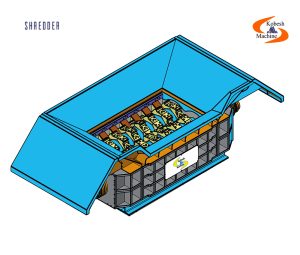

shredder

Brief Product Description A Shredder is an industrial machine designed to reduce the size of solid materials into smaller, manageable pieces. These devices have wide applications across various industries, including recycling, waste management, security (document destruction), and raw material processing. Shredders break down materials into fragments using rotating blades, significantly reducing their volume. Different models of shredders are designed to process a wide range of materials such as plastics, metals, paper, wood, rubber, and bulky items.

Structural Features shredder

- Cutting System: Includes multiple shafts equipped with specialized blades (such as single-shaft, twin-shaft, or quad-shaft blades) that rotate at different speeds to tear the materials.

- Powerful Motor: With high torque for shredding hard and dense materials.

- Feed Hopper: The material input opening, typically large and designed for easy loading.

- Hydraulic System (in some models): Used to push materials towards the blades, increasing efficiency.

- Screen / Sieve (in some models): For controlling the final particle size of the output.

- Robust Frame: Constructed from thick steel to withstand high stresses.

- PLC Control System: For precise management of operations, speed, and safety.

- Dust Collection System: For environmental hygiene and preventing pollution dispersion.

shredder

Mechanism of Operation Materials are fed into the machine via the feed hopper. The shafts equipped with blades begin to rotate. In twin-shaft or quad-shaft models, the blades on each shaft engage with each other to tear the materials. In single-shaft models, materials are pressed against a fixed counter-knife (matrix) by a rotating rotor with mounted blades and are then shredded. Depending on the type of shredder and the input materials, a hydraulic system may be used for material feeding, and a screen or sieve might be employed to determine the final particle size. The shredded product is discharged from the bottom of the machine.

Build Specifications shredder

- Blade Material: Hardened alloy steel, wear-resistant steel, with easy replacement capability.

- Frame Material: Thick carbon steel, wear-resistant steel.

- Shaft Type: Monolithic or modular shafts.

- Drive System: Heavy-duty industrial gearboxes, hydraulic drive.

- Control System: PLC panel with touch screen display, safety sensors.

Component Introduction shredder

- Component Descriptions

- Blades: The main cutting components, usually made from resistant alloy steel.

- Shafts: The rotating shafts onto which the blades are mounted.

- Hopper: The material input funnel.

- Electric Motor: Provides the driving force.

- Gearbox: A system for reducing speed and increasing torque.

- Hydraulic System (if applicable): Includes pump, cylinders, and hoses.

- Control Panel: Consists of buttons, display, and PLC.

- Air Filters for Dust Collection: For capturing airborne particles.

We are a parts manufacturer, contact us for parts procurement As a specialized manufacturer of components for all types of shredders, we produce high-quality blades made from wear-resistant alloy steels, precision-balanced shafts, and other critical components. Utilizing our original and durable parts guarantees the stable operation and long lifespan of your shredder machine. For pricing and to order spare parts, please contact us.

Projects shredder

- Description: Our shredder machines have been successfully deployed in numerous projects within the plastic recycling industry (converting bottles, containers, and plastic parts into granules), metal recycling (shredding beverage cans, light metal scrap), confidential document destruction for banks and organizations, and processing of wood and paper waste. With high reliability and the capacity to process large volumes of material, these machines have significantly assisted our clients in reducing waste management costs, increasing recycling efficiency, and obtaining quality raw materials.

Kobesh Machine stands as a symbol of durability, high productivity, and secure industrial investment.

Contact Us

To receive tailored technical consultation, review high-capacity models, and select the most suitable solution aligned with the scale of your investment, please contact our executive team directly:

Sales Manager: +98 912 661 4519 — Alipour

R&D and Engineering Manager: +98 912 365 7790 — Alipour

Our specialists are ready to support you from technical evaluation to final equipment selection for large-scale and international projects.

Take control of crushing power—secure the future of your project.