Advanced Crushing Solutions by Kobesh Machine

With decades of continuous experience in the design and manufacturing of crushing equipment, kobesh machine is recognized as a leading manufacturer in the mining and asphalt industries.

Having successfully installed thousands of crushing machines worldwide, kobesh machine has built a strong reputation for reliability, performance, and engineering excellence across mining, road construction, and asphalt plant projects.

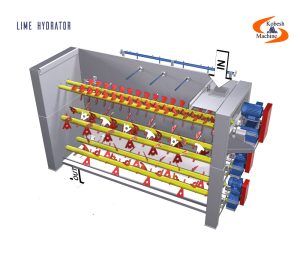

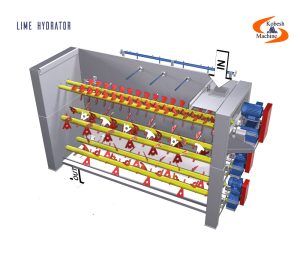

Lime Hydrator

Brief Product Description A Lime Hydrator is a chemical process where quicklime (calcium oxide, CaO) reacts with water (H₂O) to form slaked lime or hydrated lime (calcium hydroxide, Ca(OH)₂). This process, also known as “lime slaking,” is exothermic. The Lime Hydrator is designed to precisely control this reaction, manage the generated heat, and produce hydrated lime of specific quality and particle size. The final product, hydrated lime, is used in numerous industries, including water and wastewater treatment, construction (mortars and plasters), steel production, agriculture (soil amendment), and chemical manufacturing.

Structural Features lime hydrator

- Reaction Chamber: Typically a robust cylinder or vessel where the reaction takes place.

- Quicklime Feeding System: Includes a hopper and a feeder mechanism for accurate input of quicklime (lumpy or powdered).

- Water Injection System: Nozzles or injection systems for adding the precise amount of water required for the quicklime.

- Internal Agitator or Mixer: For uniform mixing of lime and water, facilitating the hydration process, and preventing product clumping.

- Heat Management System: Includes insulation layers, a cooling system (if needed), or a specific design to dissipate reaction heat.

- Product Discharge System: A mechanism for removing the produced hydrated lime.

- Temperature and Moisture Controllers: Sensors and control systems for monitoring and adjusting process parameters.

- Durable Materials: Use of wear-resistant and corrosion-resistant steel for parts in contact with lime and alkaline materials.

lime hydrator

Mechanism of Operation Quicklime (CaO) is fed into the reaction chamber via the feeding system. Simultaneously, a precise amount of water (H₂O) is added by the injection system. The exothermic reaction CaO + H₂O → Ca(OH)₂ + Heat begins. The internal agitators continuously mix the materials, ensuring all quicklime reacts with water. The heat generated is managed by the machine’s design. The resulting hydrated lime (Ca(OH)₂), produced as a fine powder or paste (depending on machine design and water content), is then discharged through the outlet system. The process is controlled to maintain the final temperature and product particle size within the desired range.

Build Specifications lime hydrator

- Body and Internal Component Material: Carbon steel with anti-wear coating, stainless steel (SS304/SS316L) for specific applications.

- Agitator Type: Paddle, screw, or blade type.

- Water Injection System: Precision spray nozzles, rotary spray system.

- Lime Feeding Mechanism: Screw feeder, conveyor belt, or weighing system.

- Insulation: Use of thermal insulation materials to maintain temperature and efficiency.

Component Descriptions lime hydrator

- Quicklime Hopper: Storage and feeding point for quicklime.

- Lime Feeder: Precise mechanism to control the input rate of lime (e.g., screw feeder).

- Water Injection System: Includes pump, piping, and nozzles.

- Reaction Chamber: The main body of the machine.

- Agitator / Mixer: Rotating parts for mixing.

- Agitator Shaft: The main drive shaft for the mixer.

- Discharge System: Includes a screw conveyor or outlet gate.

- Electrical & Control Panel: For managing the machine’s operation.

We are a parts manufacturer, contact us for parts procurement As a specialized manufacturer of Lime Hydrator components, we produce a range of high-quality spare parts, including wear-resistant agitator blades, precision feeders, corrosion-resistant reaction chamber parts, and other critical components. Using our genuine parts ensures the longevity and efficiency of your machine. Contact us for price inquiries and parts orders.

Projects lime hydrator

- Description: Our Lime Hydrators have been successfully employed in numerous projects within water and wastewater treatment industries (for pH adjustment and impurity removal), the steel industry (as a purifying agent), the construction sector (in producing mortars and building materials), and agriculture (for soil improvement). With high reliability, satisfactory production efficiency, and precise control over final product quality, these machines have significantly contributed to optimizing our clients’ industrial processes.

Kobesh Machine stands as a symbol of durability, high productivity, and secure industrial investment.

Contact Us

To receive tailored technical consultation, review high-capacity models, and select the most suitable solution aligned with the scale of your investment, please contact our executive team directly:

Sales Manager: +98 912 661 4519 — Alipour

R&D and Engineering Manager: +98 912 365 7790 — Alipour

Our specialists are ready to support you from technical evaluation to final equipment selection for large-scale and international projects.

Take control of crushing power—secure the future of your project.