Advanced Crushing Solutions by Kobesh Machine

With decades of continuous experience in the design and manufacturing of crushing equipment, kobesh machine is recognized as a leading manufacturer in the mining and asphalt industries.

Having successfully installed thousands of crushing machines worldwide, kobesh machine has built a strong reputation for reliability, performance, and engineering excellence across mining, road construction, and asphalt plant projects.

Batching Plant

Brief product description A Batching Plant (Ready-Mix Concrete Production Plant) is an industrial facility designed for the precise and automated mixing of concrete’s raw materials (cement, sand, aggregate, water, and admixtures) in specified proportions, to produce high-quality concrete. These plants play a vital role in large-scale construction projects such as dams, bridges, tunnels, high-rises, as well as in supplying concrete for mass housing and infrastructure projects.

Structural features batching plant

- Diverse Capacities: Ranging from low-capacity models (e.g., 30 m³/h) to industrial high-capacity models (e.g., 120 m³/h and above).

- Mixer Types: Includes Pan-drum mixers, Pan-helical mixers, and Twin-shaft mixers for various applications and materials.

- Precise Weighing System: High-accuracy, separate weighing systems for cement, water, aggregates (sand and gravel), and admixtures.

- Material Storage System: Aggregate storage hoppers of various capacities and cement silos (optional) for temporary storage of raw materials.

- Material Transfer System: Aggregate conveyors and elevators (Aggregate Conveyor/Transfer) and cement screws (Cement Screw) for material movement between different sections.

- Advanced Control System: Manual, semi-automatic (PLC), and fully automatic (PLC + HMI + Computer) control systems for precise management of the production process.

- Robust Design: Use of alloy steels and wear-resistant materials for mixer components, hoppers, and material pathways.

- High Reliability: Designed for continuous, long-term operation in harsh industrial conditions.

How it works batching plant

The concrete production process in a batching plant unfolds as follows:

- Material Feeding: Aggregates (sand and gravel) are conveyed via hoppers and the aggregate elevator to the mixer. Cement is transferred from a silo (if applicable) or bags using a cement screw to the cement weighing hopper. Water and admixtures are also precisely measured and introduced into the mixer.

- Weighing: Each material (cement, water, aggregates) is weighed accurately and individually by the weighing systems.

- Mixing: After weighing, all materials are fed into the mixer, where they are thoroughly and uniformly blended by the mixer blades to produce the desired quality of concrete.

- Concrete Discharge: The ready-mix concrete is discharged from the mixer and transported to a truck mixer or the point of use.

- Process Control: The control system manages and monitors all stages of weighing, feeding, and mixing according to the programmed settings.

Build specifications batching plant

- Mixer Material: Wear-resistant and corrosion-resistant alloy steels.

- Hopper and Chute Material: Carbon steel with resistant coating or stainless steel.

- Conveyor Belt: Durable and abrasion-resistant materials.

- Cement Silo: Galvanized or steel sheets of appropriate thickness.

- Electrical Control Panel and System: Industrial standard equipment from reputable brands.

- Frame and Structure: High-strength steels.

- Aeration System (Compressor): With adequate capacity for pneumatic systems (such as pneumatic valves and cement screws).

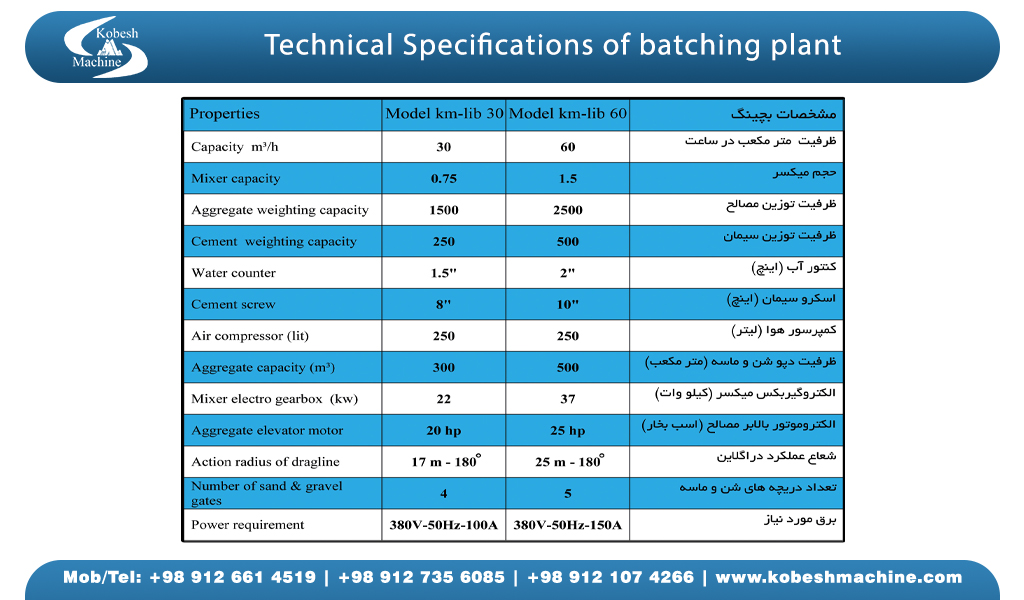

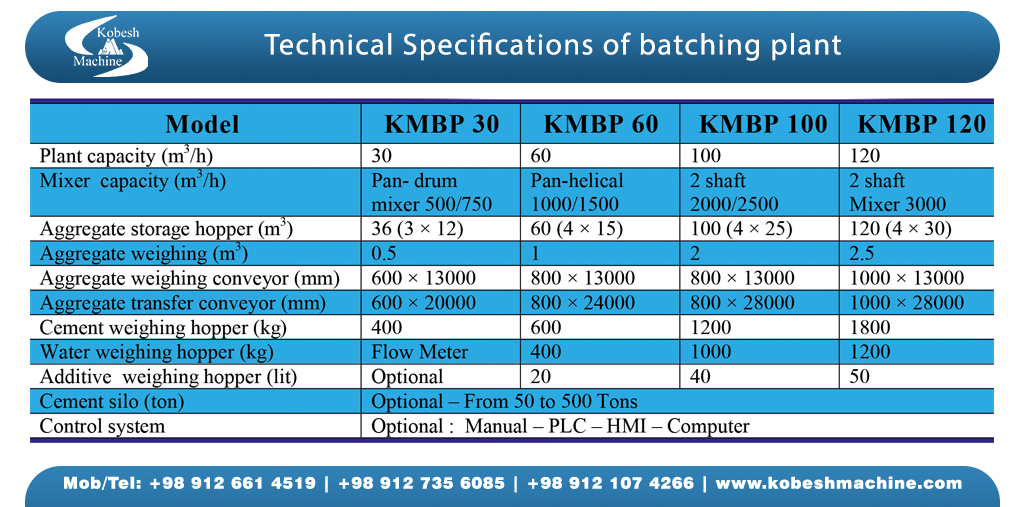

Technical specifications table batching plant

- Model: KMBP 30 / KMBP 60 / KMBP 100 / KMBP 120

- Production Capacity (m³/h): 30 / 60 / 100 / 120

- Mixer Volume (Lit): 500-750 / 1000-1500 / 2000-2500 / 3000

- Aggregate Weighing Capacity (kg): 1500 / 2500 / (2000 / 2500 – not explicitly detailed in kg for 100/120 models on the source image, but implied for aggregates)

- Cement Weighing Capacity (kg): 250 / 500 / 1200 / 1800

- Aggregate Hopper Capacity (m³): 36 / 60 / 100 / 120

- Control System: Manual / PLC / HMI / Computer (Optional)

- Mixer Motor Power (kW): 22 / 37 / (Not specified for 100 & 120, but likely similar or higher)

- Aggregate Elevator Motor Power (hp): 20 / 25 / (Not specified for 100 & 120, but likely similar or higher)

Component Descriptions batching plant

- Mixer: The core of the batching plant responsible for mixing the materials.

- Hoppers: Temporary storage bins for aggregates.

- Cement Silo: Storage tank for cement (if silos are used).

- Weighing System: Includes load cells, indicators, and control valves for precise material measurement.

- Aggregate Conveyor/Elevator: For transporting aggregates from hoppers to the mixer.

- Cement Screw Conveyor: For transporting cement from the silo or discharge point to the cement weighing hopper.

- Control System: Consists of PLC, HMI, computer, sensors, and electrical panel.

- Air Compressor: Supplies compressed air for pneumatic components (like pneumatic valves and cement screws).

- Frame & Structure: The main framework of the batching plant.

We are a parts manufacturer, contact us for parts procurement As a reputable manufacturer of batching plant components, we produce a wide range of high-quality parts, including mixer blades, wear-resistant liners, weighing hoppers, elevator systems, cement screws, control system components, and other essential parts. Ensuring the quality and precision of spare parts is crucial for maintaining the efficiency and extending the lifespan of your batching plant. Contact us for price inquiries and consultation regarding your required parts.

Projects batching plant

- Description: Our batching plants have been successfully deployed in numerous civil engineering and infrastructure projects, including the construction of airports, highways, high-rise buildings, mass housing projects, and ready-mix concrete production facilities. The variety of models and customization capabilities enable these machines to meet the precise requirements of each project, from capacity and concrete type to environmental conditions. The satisfaction of our clients in domestic and international projects testifies to the quality and reliability of our products.

Kobesh Machine stands as a symbol of durability, high productivity, and secure industrial investment.

Contact Us

To receive tailored technical consultation, review high-capacity models, and select the most suitable solution aligned with the scale of your investment, please contact our executive team directly:

Sales Manager: +98 912 661 4519 — Alipour

R&D and Engineering Manager: +98 912 365 7790 — Alipour

Our specialists are ready to support you from technical evaluation to final equipment selection for large-scale and international projects.

Take control of crushing power—secure the future of your project.