Advanced Crushing Solutions by Kobesh Machine

With decades of continuous experience in the design and manufacturing of crushing equipment, kobesh machine is recognized as a leading manufacturer in the mining and asphalt industries.

Having successfully installed thousands of crushing machines worldwide, kobesh machine has built a strong reputation for reliability, performance, and engineering excellence across mining, road construction, and asphalt plant projects.

Conveying Machinery

Conveying Machinery refers to a set of vital industrial equipment designed for the continuous movement, lifting, and transportation of bulk materials, packages, and products across various industrial processes. These systems play a crucial role in optimizing production lines, reducing labor requirements, and enhancing speed and efficiency in industries such as mining, agriculture, construction, food processing, petrochemicals, and logistics.

Structural features conveying machinery

- High Variety: Includes various types of conveyors such as belt conveyors (fixed and mobile), screw conveyors, elevators, overhead conveyors, chain conveyors, roller conveyors, and bucket elevators.

- Robust and Durable Design: Utilization of high-strength industrial steels, wear-resistant and corrosion-resistant alloys, and high-quality conveyor belts.

- Powerful Drive System: Employment of standard electric motors, industrial gearboxes, and reliable power transmission systems.

- Modular and Customizable Design: Ability to design and manufacture based on specific project requirements, including dimensions, capacity, conveying angle, and material type.

- Advanced Control Systems: Potential for automation of the conveying process using PLCs, sensors, and monitoring systems.

- Quality Components: Use of durable rollers, pulleys, bearings, and connectors for smooth and long-lasting operation.

How it works (mechanism) The operating mechanism varies depending on the type of equipment:

- Belt Conveyor: A continuous belt placed on a series of rollers and pulleys. As the head pulley rotates, driven by a motor and gearbox, the belt moves, transporting materials placed on it from the loading point to the discharge point.

- Screw Conveyor: Consists of a helical shaft (flight) enclosed within a tube or trough. As the shaft rotates, it pushes the material forward for transportation.

- Elevator: Used for vertical material transport, typically employing buckets mounted on a moving chain or belt.

- Other Conveyors: Various mechanisms like rotating rollers, moving chains, or airflow (in air chutes and air slides) are used for material transfer.

Build specifications conveying machinery

- Frame and Structure Material: Carbon steel, stainless steel, or wear-resistant alloys depending on the application.

- Conveyor Belt Material: Rubber, PVC, PU, steel, or fabric with varying resistance to heat, abrasion, and chemicals.

- Motor and Gearbox: Industrial standard with high efficiency and continuous operation capability.

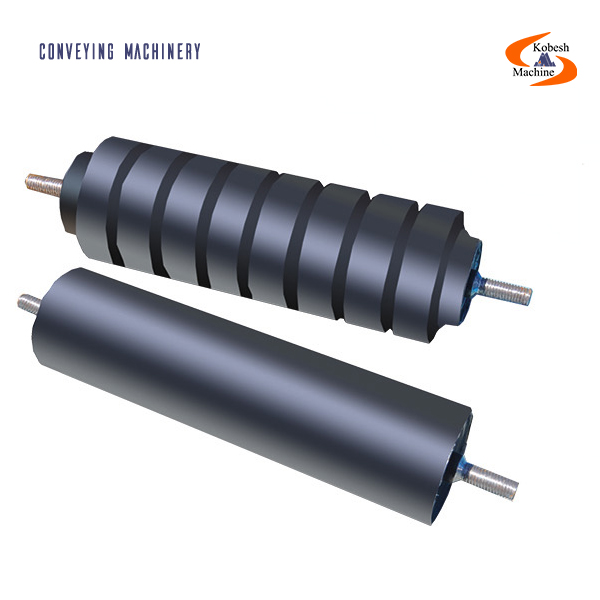

- Rollers and Pulleys: Made from steel with resistant coatings or polymer materials.

- Bearings: From reputable brands and high quality to ensure smooth operation.

- Connectors: Robust and durable for connecting belts or chains.

- Control System: Includes electrical panel, PLC, inverter, and safety sensors.

Technical specifications table conveying machinery

- Equipment Type: Fixed Belt Conveyor / Mobile Conveyor / Screw Conveyor / Elevator / Chain Conveyor / …

- Belt Width (for Belt Conveyors): (e.g., 400mm to 2000mm)

- Conveyor Length: (e.g., 5 meters to 100 meters or more)

- Transport Capacity: (e.g., 10 tons/hour to 1000 tons/hour)

- Conveying Angle (for Elevators and some Belt Conveyors): (e.g., 0 to 90 degrees)

- Motor Power: (e.g., 1.5kW to 100kW)

- Belt/Transport Speed: (e.g., 0.1 m/s to 2.5 m/s)

- Materials Conveyed: Bulk materials, powders, granules, packaged goods, stone, coke, cement, fertilizer, food products, etc.

- Operating Temperature: (Specific temperature range based on materials and environment)

Component Descriptions conveying machinery

- Conveyor Belt: The primary material-carrying surface.

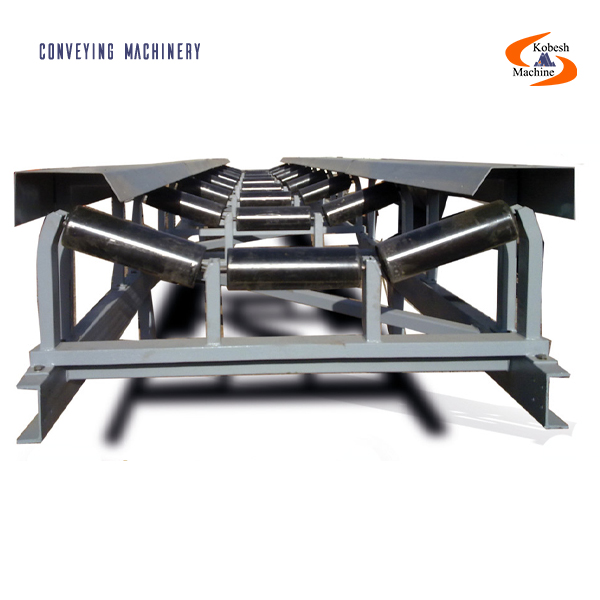

- Rollers/Idlers: Support the belt and reduce friction.

- Pulleys: Including head pulley (drive), tail pulley (return), and tensioning pulleys.

- Motor & Gearbox: Provide the driving power.

- Frame & Structure: The main skeletal support for the entire system.

- Brackets & Supports: Hold the rollers and frame.

- Bearings: Friction-reducing components in rollers and pulleys.

- Screw/Flight: The rotating helical component in screw conveyors.

- Bucket: Used in elevators for vertical material transport.

- Chain/Belt Connectors: For joining belt or chain sections.

We are a parts manufacturer, contact us for parts procurement As a leading manufacturer of conveying machinery parts, we offer a wide range of high-quality components. From durable conveyor belts, precision rollers and pulleys, to reliable motors, gearboxes, bearings, and robust connectors. We understand that the quality of spare parts is vital for maintaining operational efficiency and minimizing your production line downtime. Contact us to procure the best parts for your conveying machinery.

Projects

- Description: Our conveying machinery has been successfully installed and commissioned in major industrial projects within sectors such as mining (e.g., transporting ore and raw materials), cement plants, petrochemical facilities, food processing industries (handling grains and products), ports (for ship loading and unloading), and logistics warehouses. Customized design, high reliability, and the ability to operate in harsh environmental conditions make these systems an ideal choice for a wide array of applications.

Kobesh Machine stands as a symbol of durability, high productivity, and secure industrial investment.

Contact Us

To receive tailored technical consultation, review high-capacity models, and select the most suitable solution aligned with the scale of your investment, please contact our executive team directly:

Sales Manager: +98 912 661 4519 — Alipour

R&D and Engineering Manager: +98 912 365 7790 — Alipour

Our specialists are ready to support you from technical evaluation to final equipment selection for large-scale and international projects.

Take control of crushing power—secure the future of your project.