Kobesh Machine | Engineering Solutions for Mining & Asphalt Plants

At Kobesh Machine, we specialize in the design, manufacturing, and supply of mining machinery and asphalt plant equipment, delivering reliable and high-performance solutions for industrial projects. By combining technical expertise with hands-on industry experience, we produce durable machines that meet the demanding requirements of mining operations, crushing lines, and road construction projects.

In addition to manufacturing equipment such as crushers, feeders, screens, and asphalt plant systems, we also produce and supply spare parts and provide dependable technical support to our clients. Our strong presence in numerous mining, sand and gravel, asphalt, and cement projects reflects our commitment to quality, operational efficiency, and long-term customer satisfaction.

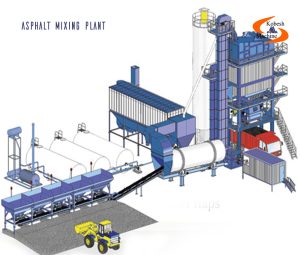

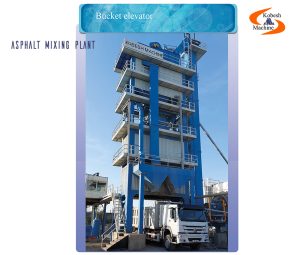

Asphalt mixing plant

Product Review For high-quality asphalt, the hot mix asphalt plant with capacities of 80–200 t/h for stationary plants and 100 t/h for mobile units, with mineral temperature rise up to 160°C, maximum aggregate size 25 mm, and a maximum cycle of 80 batches per hour. The asphalt specific weight is 1.8 t/m³.

Brief product description This product provides a complete set of units without the need for additional configuration, including cold feed, belt conveyors, cylindrical dryer, Turbo Jet dual-fuel burner, screening deck, a mixer with wear-resistant replaceable parts, and precise measurement and control systems. The main components are designed for high efficiency to deliver a stable process of heating, drying, and mixing with optimized fuel consumption.

Asphalt maxing plant

Mechanism of operation The cold material is fed by the cold feeder onto the drum surface and is guided to the dryer unit by separate belt feeds for each silo using extendable baskets. In the cylindrical dryer, crushing and heat transfer occur together to dry the aggregates so they are ready to be mixed with bitumen. The dual-fuel Turbo Jet burner provides the necessary heat, and the screening and weighing system ensures precise mixing. The mixer, with wear-resistant, replaceable parts, blends the materials in accurate proportions and then stores them in separate silo tanks. All processes are controlled from the central cabin using precise measurement systems. asphalt mixing plant

Structural features Asphalt maxing plant

- Extendable cold feeder bins with 4 or 5 standard bins

- Interchangeable silo walls with a capacity of about 9 m³ per silo and separate dosing belts per silo

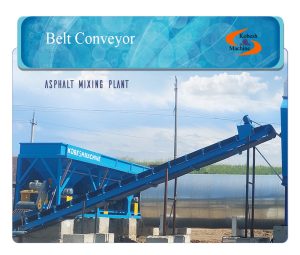

- Belt conveyor to feed cold material into the drying unit: length 11 m, width 0.6 m, 4 kW drive

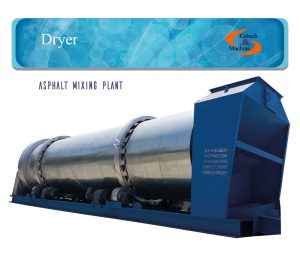

- Drying unit: cylindrical type with four 11 kW drives, diameter 180–220 cm, length 8–9.5 m, steel or galvanized cover, heavy-duty chassis, optimized paddle design for maximum heat exposure

- Turbo Jet dual-fuel burner with capacity 8,000,000–16,000,000 Kcal

- Screening deck for asphalt mixing with four or five hot bins for four or five mineral sizes, featuring sample collection doors for analytical purposes asphalt mixing plant

- Total screen area: 18 m²; sand deck area: 4.5 m²

- Drive unit: 15 kW or two 15 kW units

- Dust removal duct with adjustable flaps and vibration amplitude via eccentric wheel

- Mixer: wear-resistant parts and replaceable; full mixing tower is easily and safely accessible; mineral, filler, and bitumen scales

- Mineral scale: 4 × 1000 kg load cells; filler scale: 3 × 500 kg load cells; bitumen scale: 3 × 500 kg load cells

- Capacity: 1500 up to 3000 kg, 120–160–200 t/h asphalt mixing plant

Construction specifications asphalt mixing plant

- General size and design in line with 80–120–160–200 t/h for stationary plants and 100 t/h for mobile units

- Final asphalt bulk density: approximately 1.8 t/m³

- Electronic controls and measurement systems using load cells for minerals, filler, and bitumen

Technical specifications table asphalt mixing plant

- Working capacity: 1500 to 3000 kg per batch or 120–160–200 t/h across different models

- Dryer unit: cylindrical, about 8 to 9.5 meters long and 1.8 to 2.2 meters in diameter

- Burner capacity: 8–16 million kcal

- Main motor power: typically 4×KW for various configurations

- Overall dimensions and exact weight depend on the chosen model

Introduction of device components asphalt mixing plant

- Cold feeding: cold units with extendable baskets; each silo is individually controlled by separate belt feed dosing

- Conveyors: belt conveyors with specified length and width to feed cold material into the dryer

- Dryer: cylindrical body with steel or galvanized caps and a paddle-shaped design for maximum heat transfer

- Turbo Jet dual-fuel burner: equipped with a fuel pumping system, suitable air fan, and single-nozzle design

- Screen: screen deck with various sizes and sampling areas for laboratory analyses

- Mixer: wear-resistant consumable parts with safe access for inspection

- Measurement and weighing system: load cells for minerals, filler, and bitumen

- Tanks and heating systems: bitumen tanks, heating systems, and auxiliary motors

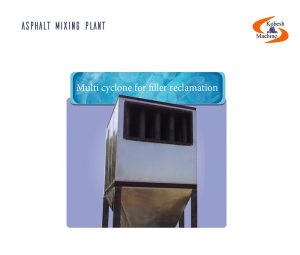

- Waste and dust collection: filters, indicators, and exhaust fans

- Other components: bucket elevator, maintenance platform with access stairs and inlet chute/manhole, and balanced suspension system asphalt mixing plant

We are also a manufacturer of parts To obtain spare parts and warranties for the equipment, contact us. We manufacture and supply a complete range of components including cold feeding with belt feeders, conveyors, dryer unit, Turbo Jet burner, multi-cyclone groups for filler collection, pumps and vacuum/filtration systems, hot and bitumen handling elevators, vibrator and weighing/mixing systems, bitumen heating and circulation, finished product silos, control cabin, and other electrical and pneumatic components.

Projects

This section covers completed projects and real-world applications. Related images can be displayed here to give customers a better sense of performance and results.

Table Key information at a glance: These units offer a combined capacity of 1500 to 3000 kg per batch or 120 to 200 t/h, include a cylindrical dryer with adjustable diameter and length, and a dual-fuel burner. The final asphalt has a bulk density of about 1.8 t/m³, and the screening system features a total area of 18 m² with accessible sampling areas. For more information and spare parts, contact our team.

Kobesh Machine stands as a symbol of durability, high productivity, and secure industrial investment.

Contact Us

To receive tailored technical consultation, review high-capacity models, and select the most suitable solution aligned with the scale of your investment, please contact our executive team directly:

Sales Manager: +989126614519 Mr. Alipour

R&D and Engineering Manager: +989123657790 Mr. Alipour (24/7)

Our specialists are ready to support you from technical evaluation to final equipment selection for large-scale and international projects.

Take control of crushing power—secure the future of your project.