Advanced Crushing Solutions by Kobesh Machine

With decades of continuous experience in the design and manufacturing of crushing equipment, kobesh machine is recognized as a leading manufacturer in the mining and asphalt industries.

Having successfully installed thousands of Vibrating Grizzly Feeder With Motor Vibrator worldwide, kobesh machine has built a strong reputation for reliability, performance, and engineering excellence across mining, road construction, and asphalt plant projects.

Technical data are approximates and should be used as guide only. Capacity and power requirements depend on the type and characteristic of the feed material.

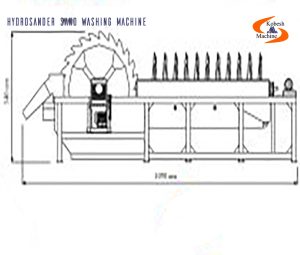

The hydrasander is used for dewatering and removing the slit content from wash sand. The large diameter bucket wheel, long fines recovery spiral and low power requirements enables these units to be both efficient and cost-effective.

Each hydrasander has a contra-flow screw recovery spiral fitted in the claim are of the tank. This spiral plays a very important role when the product to be processed contains a high percentage of fine or lower density particles. Depending on the waterfowl rate a certain percentage of bottom fines can escape first pass recovery and they are then influenced by the water flow along the settlement tank towards the weir system at the opposite end. As these fine particles move along they gravitate towards the tank bottom and into contact with the spiral blades. These influence a contra-flow system nudging the escaping fines back into the recovery buckets. In general the contra-flow spiral system maximizes efficiency of particle recovery and overall output.

Technical data are approximates and should be used as guide only. Capacity and power requirements depend on the type and characteristic of the feed material.

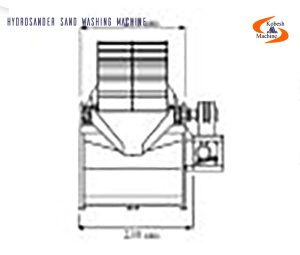

The hydrasander is used for dewatering and removing the slit content from wash sand. The large diameter bucket wheel, long fines recovery spiral and low power requirements enables these units to be both efficient and cost-effective.

Each hydrasander has a contra-flow screw recovery spiral fitted in the claim are of the tank. This spiral plays a very important role when the product to be processed contains a high percentage of fine or lower density particles. Depending on the waterfowl rate a certain percentage of bottom fines can escape first pass recovery and they are then influenced by the water flow along the settlement tank towards the weir system at the opposite end. As these fine particles move along they gravitate towards the tank bottom and into contact with the spiral blades. These influence a contra-flow system nudging the escaping fines back into the recovery buckets. In general the contra-flow spiral system maximizes efficiency of particle recovery and overall output.

Kobesh Machine stands as a symbol of durability, high productivity, and secure industrial investment.

Contact Us

To receive tailored technical consultation, review high-capacity models, and select the most suitable solution aligned with the scale of your investment, please contact our executive team directly:

Sales Manager: +989126614519 Mr. Alipour

R&D and Engineering Manager: +989123657790 Mr. Alipour (24/7)

Our specialists are ready to support you from technical evaluation to final equipment selection for large-scale and international projects.

Take control of crushing power—secure the future of your project.