Vibrating Grizzly Feeder With Motor Vibrator And Reciprocationg Feeder

Advanced Crushing Solutions by Kobesh Machine

With decades of continuous experience in the design and manufacturing of crushing equipment, kobesh machine is recognized as a leading manufacturer in the mining and asphalt industries.

Having successfully installed thousands of Vibrating Grizzly Feeder With Motor Vibrator worldwide, kobesh machine has built a strong reputation for reliability, performance, and engineering excellence across mining, road construction, and asphalt plant projects.

Product Overview / Vibrating Grizzly Feeder

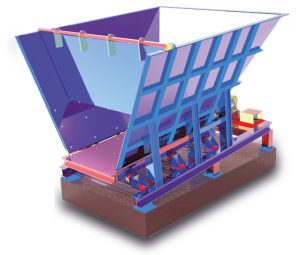

The Vibrating Grizzly Feeder is a high-capacity feeding and pre-screening machine designed to deliver material uniformly while separating fine particles before entering the crusher. This feeder is an ideal alternative to apron feeders and large reciprocating table feeders in crushing and mining operations.

Key Features of Vibrating Grizzly Feeder

Structural Features

Heavy-duty body manufactured from robust steel plates

Replaceable wear-resistant plates installed on the bottom and side walls

Integrated grizzly bar section at the discharge end to increase capacity and separate fine material

Stable operation with wet, contaminated materials and materials containing a high percentage of clay

Adjustable vibration amplitude and frequency via a steel eccentric shaft system

Vibrating Grizzly Feeder With Motor Vibrator

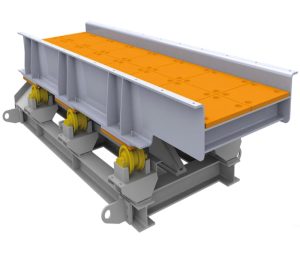

The Vibrating Grizzly Feeder is a key piece of equipment in crushing and mineral processing lines, designed for controlled and uniform feeding of coarse, bulky, and wet materials into crushers and downstream equipment. Utilizing powerful vibration motors and a robust vibrating mechanism, this machine delivers stable and reliable performance under heavy-duty operating conditions.

Structural Features

Heavy-duty steel body with reinforced industrial design

Equipped with high-performance vibration motors

Suitable for high-capacity operation

Designed for feeding coarse-grained and wet materials

Reinforced structure for installation in fixed mineral processing lines

Adjustable vibration intensity to control the feed rate Vibrating Grizzly Feeder With Motor Vibrator

Operating Mechanism Description

The operation of the Vibrating Grizzly Feeder is based on mechanical vibration generated by vibration motors. This vibration causes gradual and uniform movement of mineral materials along the feeder deck, ensuring steady feeding to downstream equipment such as crushers.

In models equipped with a reciprocating feeder system, the back-and-forth movement of the feeder trolley resting on rollers allows efficient feeding of large quantities of coarse and wet materials.

Construction Specifications

Designed for feeding primary crushers

Suitable for mining, aggregate, and mineral processing industries

Engineered for continuous and long-term operation

Capable of operating under harsh environmental conditions and heavy loads

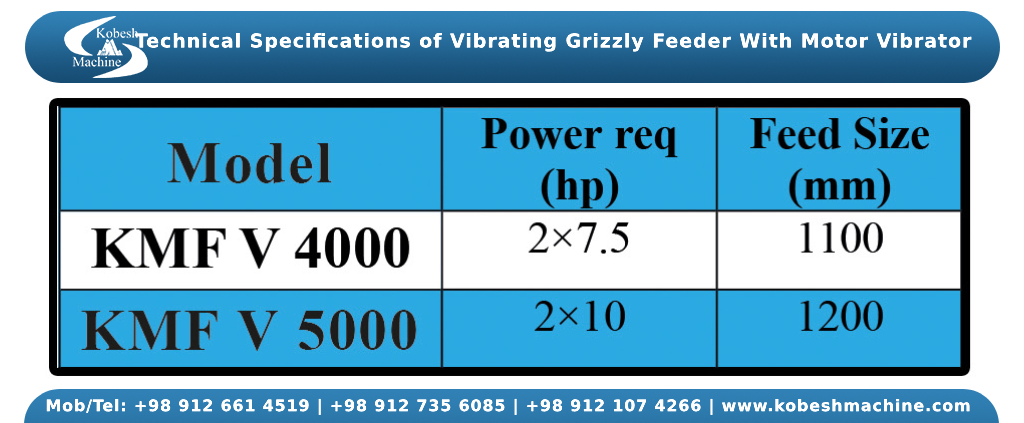

Table Data Description

The Vibrating Grizzly Feeder is available in two models: KMF V 4000 and KMF V 5000. The KMF V 4000 model is designed with a power requirement of two 7.5-horsepower motors and features a 1100 mm feed opening. The more powerful KMF V 5000 model utilizes two 10-horsepower motors and offers a larger 1200 mm feed opening, making it suitable for higher capacities and coarser materials.

Spare parts and components of Vibrating Grizzly Feeder With Motor Vibrator And Reciprocationg Feeder

Vibration Motors: Generate uniform and stable vibration for material movement

Main Body and Frame: Designed to withstand heavy loads and continuous vibration

Feeder Tray / Deck: Surface for holding and transferring mineral materials

Roller System and Reciprocating Mechanism (in applicable models): Enables feeding of bulky and wet materials

Industrial Supports and Connections: Ensure safe and stable installation in the production line

👉 Important Note:

We are manufacturers of the machine components, and we supply all spare parts for the Vibrating Grizzly Feeder, including vibration motors, frames, trays, and mechanical components.

📞 Please contact us for spare parts supply and technical consultation.

Vibrating Grizzly Feeder With Motor Vibrator

Projects

The supplied Vibrating Grizzly Feeders have been used in various mineral processing and crushing projects, particularly in open-pit mines. These machines play a crucial role in improving production line efficiency and ensuring consistent feeding to crushing equipment.

Kobesh Machine stands as a symbol of durability, high productivity, and secure industrial investment.

Contact Us

To receive tailored technical consultation, review high-capacity models, and select the most suitable solution aligned with the scale of your investment, please contact our executive team directly:

Sales Manager: +989126614519 Mr. Alipour

R&D and Engineering Manager: +989123657790 Mr. Alipour (24/7)

Our specialists are ready to support you from technical evaluation to final equipment selection for large-scale and international projects.

Take control of crushing power—secure the future of your project.