Vibrating Grizzly Feeder

Advanced Crushing Solutions by Kobesh Machine

With decades of continuous experience in the design and manufacturing of crushing equipment, kobesh machine is recognized as a leading manufacturer in the mining and asphalt industries.

Having successfully installed thousands of crushing machines worldwide, kobesh machine has built a strong reputation for reliability, performance, and engineering excellence across mining, road construction, and asphalt plant projects.

Vibrating Grizzly Feeder

The Vibrating Grizzly Feeder is a high-capacity feeding and pre-screening machine designed to deliver material uniformly while separating fine particles before entering the crusher. This feeder is an ideal alternative to apron feeders and large reciprocating table feeders in crushing and mining operations.

Structural Features

Heavy-duty body manufactured from robust steel plates

Replaceable wear-resistant plates installed on the bottom and side walls

Integrated grizzly bar section at the discharge end to increase capacity and separate fine material

Stable operation with wet, contaminated materials and materials containing a high percentage of clay

Adjustable vibration amplitude and frequency via a steel eccentric shaft system

Operating Mechanism Description

The Vibrating Grizzly Feeder operates by generating controlled vibrations that move material forward in a uniform flow. At the same time, the grizzly bar section installed at the outlet separates fine particles before they enter the crusher. This dual-function mechanism improves overall plant efficiency, reduces unnecessary load on the crusher, and minimizes wear on downstream equipment.

Manufacturing Specifications

Designed for pre-screening and separation of small to medium-sized material

Available with single or double-level grizzly screening decks

Optional wire mesh screen at the lower section for finer material separation

Suitable for cement plants, mining operations, and heavy-duty crushing lines

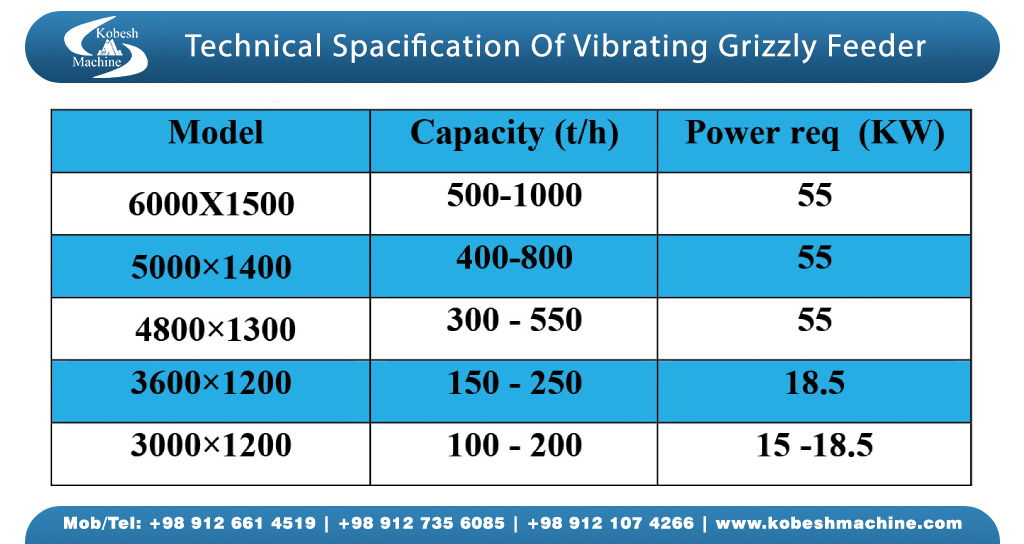

Technical Table Analysis

According to the technical specifications table, the Vibrating Grizzly Feeder is available in five different models with capacities ranging from 100 to 1000 tons per hour. The 6000 × 1500 model offers the highest capacity while operating with a 55 kW motor, making it suitable for heavy-duty crushing lines. Smaller models such as the 3000 × 1200 provide capacities of 100 to 200 t/h with power requirements between 15 and 18.5 kW, offering an efficient and economical solution for medium and small-scale projects. This wide range of models allows precise selection based on plant capacity and operational requirements.

Spare parts and components vibrating grizzly feeder

Feeder Body: Heavy-duty steel structure designed to withstand high stress and abrasive conditions

Vibration System: Steel eccentric shafts enabling adjustment of vibration amplitude and frequency

Grizzly Bar Section: Separates fine material and reduces the load entering the crusher

Wear-Resistant Plates: Replaceable liners installed on the bottom and sides to extend service life

Electric Motor and Power Transmission System: Selected according to feeder model and capacity

👉 We are also a manufacturer of spare parts for this machine. All spare parts, including shafts, wear plates, grizzly bars, and vibration assemblies, are available.

📞 Please contact us for spare parts supply and technical support.

Projects

The Vibrating Grizzly Feeder has been successfully installed in various mining projects and crushing plants with different capacities. It is commonly used as a feeding and pre-screening unit before jaw crushers and impact crushers. Reliable performance under harsh working conditions and with contaminated materials has made this feeder a trusted solution in industrial projects.

Kobesh Machine stands as a symbol of durability, high productivity, and secure industrial investment.

Contact Us

To receive tailored technical consultation, review high-capacity models, and select the most suitable solution aligned with the scale of your investment, please contact our executive team directly:

Sales Manager: +989126614519 Mr. Alipour

R&D and Engineering Manager: +989123657790 Mr. Alipour (24/7)

Our specialists are ready to support you from technical evaluation to final equipment selection for large-scale and international projects.

Take control of crushing power—secure the future of your project.