Advanced Crushing Solutions by Kobesh Machine

With decades of continuous experience in the design and manufacturing of crushing equipment, kobesh machine is recognized as a leading manufacturer in the mining and asphalt industries.

Having successfully installed thousands of crushing machines worldwide, kobesh machine has built a strong reputation for reliability, performance, and engineering excellence across mining, road construction, and asphalt plant projects.

Product Overview

Application of Impact Crushers

Impact Crushers are designed for efficient crushing of a wide range of hard and semi-hard materials, including mountain rocks and river stones. These machines are capable of handling large feed sizes while delivering high reduction ratios, making them an ideal solution for secondary and tertiary crushing stages.

The end product produced by impact crushers is uniform, well-graded, and highly cubical aggregate, which fully meets the requirements of high-quality concrete production and industrial asphalt plants. Their ability to shape aggregates makes impact crushers a preferred choice in applications where product quality and shape are critical.

Available Configurations

Impact crushers are available in various models and configurations to match different production capacities and project requirements—from medium-scale operations to high-capacity crushing lines in mining and large asphalt plants.

Key Features of Impact Crushers

All industrial Impact Crushers offer the following key advantages:

High reduction ratio compared to compression-type crushers

Production of cubical-shaped aggregates with excellent particle geometry

Accurate control over output size and gradation

Efficient crushing performance with optimized energy consumption

Long service life of wear parts made from high-quality, wear-resistant materials

Easy inspection and maintenance through access doors and hydraulic systems

Reliable and stable operation under continuous and heavy-duty working conditions

Vertical Shaft Impact Crusher

The Vertical Shaft Impact Crusher (VSI) is one of the most advanced crushing machines used in the tertiary crushing stage, designed to produce high-quality sand with a cubical particle shape. This machine relies on high-speed rock-on-rock impact, delivering uniform and premium aggregates suitable for concrete, asphalt, and construction projects. Modern design, high efficiency, and low operating costs are among the key advantages of this crusher.

The Kobesh Machine VSI crusher is a powerful solution for final-stage crushing and sand production. With various capacity ranges and optimized energy consumption, it effectively meets the demands of mines and aggregate production plants.

Structural Features Of Vertical Shaft Impact Crusher

Engineered design for tertiary crushing applications

Heavy-duty and robust structure suitable for high tonnage operations

Ability to produce uniform, cubical-shaped aggregates

Easy access to internal parts for maintenance and servicing

Available in stationary or mobile (trailer-mounted) configurations

Reduced operational and initial capital costs

Operating Mechanism Description

In a VSI crusher, feed material enters through the feed hopper into the rotor, where it is accelerated at high speed. The material then impacts against other particles or wear parts inside the crushing chamber. This impact-based crushing method results in high-quality output with excellent cubical shape, making it ideal for standard sand production.

Construction Specifications

Machine Type: Vertical Shaft Impact Crusher (VSI)

Application: Tertiary crushing and sand production

Output Product: Fine and uniform sand and aggregates

Manufacturer: Kobesh Machine

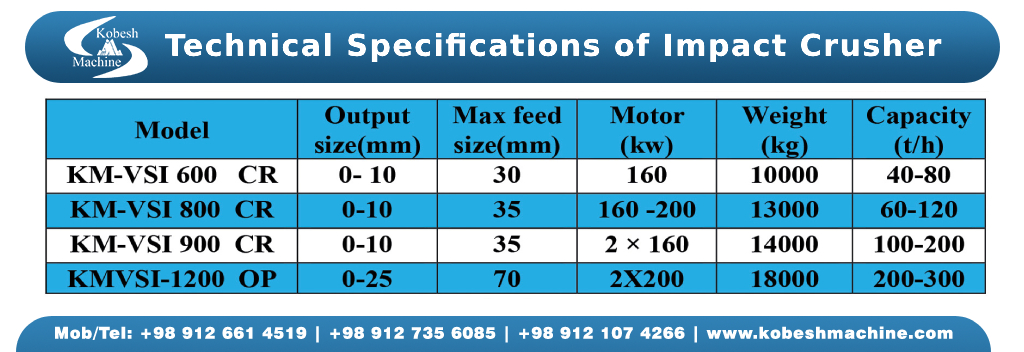

Technical Table Analysis

Based on the technical specifications table, Kobesh Machine VSI crushers are capable of producing output sizes ranging from 0 to 10 mm (and up to 0 to 25 mm for the 1200 model). The maximum feed size varies between 30 and 70 mm, while motor power ranges from 160 to 400 kW. Machine weights range from 10 to 18 tons, with production capacities between 40 and 300 tons per hour. This wide range of specifications allows for optimal model selection for projects of various scales.

Spare parts and components of VSI Crusher

Vertical Shaft Impact Crushers (VSI) are composed of a range of heavy-duty and precisely engineered components, each playing a vital role in ensuring stable operation, high efficiency, and long service life. The main components of a VSI crusher include wear parts, rotor assemblies, shafts, bushings, bearings, and the main housing structure. These components are specifically designed to withstand high-speed impact forces and abrasive working conditions commonly found in mining and aggregate production environments.

We are a parts manufacturer, contact us to get parts. Vertical Shaft Impact Crusher

Projects

Kobesh Machine VSI crushers have been installed and operated in numerous mining, construction, and aggregate production projects across the country. These machines have demonstrated stable operation, high capacity, and excellent product quality in both stationary and mobile crushing lines.

Kobesh Machine stands as a symbol of durability, high productivity, and secure industrial investment.

Contact Us

To receive tailored technical consultation, review high-capacity models, and select the most suitable solution aligned with the scale of your investment, please contact our executive team directly:

Sales Manager: +989126614519 Mr. Alipour

R&D and Engineering Manager: +989123657790 Mr. Alipour (24/7)

Our specialists are ready to support you from technical evaluation to final equipment selection for large-scale and international projects.

Take control of crushing power—secure the future of your project.