Advanced Crushing Solutions by Kobesh Machine

With decades of continuous experience in the design and manufacturing of crushing equipment, kobesh machine is recognized as a leading manufacturer in the mining and asphalt industries.

Having successfully installed thousands of crushing machines worldwide, kobesh machine has built a strong reputation for reliability, performance, and engineering excellence across mining, road construction, and asphalt plant projects.

General Introduction of Cone Crusher

The Cone Crusher is one of the main pieces of equipment used in crushing lines for mining, sand and aggregate production, and mineral processing industries. This machine crushes stones by applying compressive force between the mantle and the concave, using the rotary motion of the main shaft to produce uniform and controlled particle sizes.

Applications

Secondary and tertiary crushing in mining operations

Aggregate and construction material production

Sand and gravel crushing lines

Crushing of hard and semi-hard rocks

Types of Cone Crushers

Based on the catalog images, the following cone crusher types are available:

🔹 Standard Cone Crusher

Suitable for conventional crushing applications

Classic mechanical design

Various models with fixed power rating (90 kW for 36-inch models)

🔹 Hydro Cone Crusher CH-CS

Equipped with a hydraulic system (Hydroset)

Fast and accurate setting adjustment

Higher safety and reduced downtime

Designed for heavy-duty industrial applications

🔹 GP Series Cone Crusher

Cone crusher design focused on high-capacity production

Suitable for high-tonnage crushing lines

Stable and continuous performance

Common Features of All Models

The following features are common across all cone crusher models shown in the catalog:

Heavy-duty vertical main shaft

Wear-resistant mantle and concave liners

Dust sealing system (Dust Seal Ring)

Industrial-grade bearings and bushings

Designed for continuous operation in crushing lines

High-capacity output with uniform product size

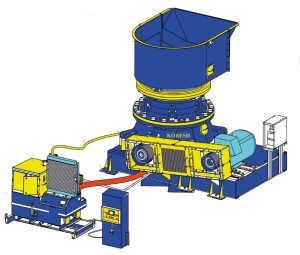

GP Series Cone Crusher

The GP Series Cone Crusher is a high-efficiency crushing machine designed for high-capacity production and precise particle size control in crushing plants. With its robust structure and adjustable Closed Side Setting (CSS), this crusher is an ideal solution for secondary and tertiary crushing applications in mining and aggregate industries.

Structural Features

Heavy-duty and rigid body construction

High-strength vertical main shaft

Lubrication and cooling system equipped with an Oil Radiator

Precise adjustment of crushing gap (Closed Side Setting – CSS)

Multiple model configurations (S, EC, C, M, MF, F, EF) for different applications

Designed for continuous operation and high production capacity

Working Mechanism

In the GP Series Cone Crusher, material is fed from the top of the machine and compressed between the mantle and the concave. The eccentric movement of the main shaft generates compressive force, resulting in effective crushing. The adjustable CSS allows accurate control of the final product size, enabling operators to meet various production requirements.

Construction Specifications

Industrial-grade steel body

Power transmission system with motor and gearbox

Integrated lubrication and oil cooling system

Suitable for fixed installation in crushing plants

Wear-resistant internal components

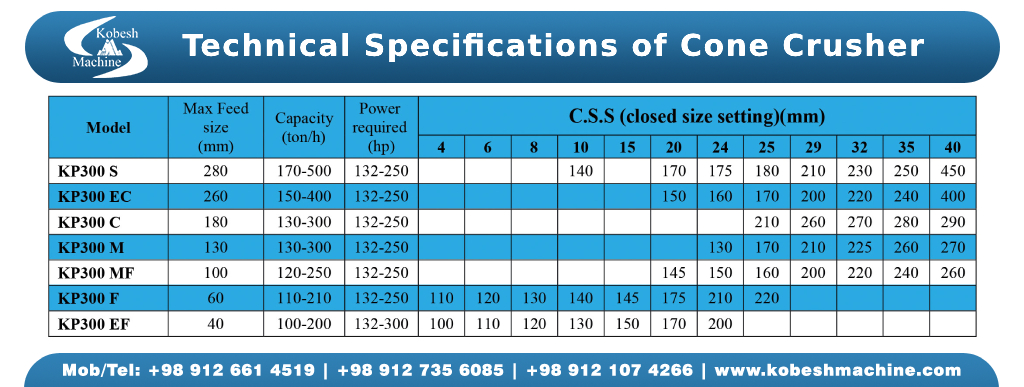

Analysis of the Technical Table

The GP Series Cone Crusher technical data demonstrates that the KP300 models cover a broad range of crushing requirements. Maximum feed size varies from 40 mm to 280 mm, while production capacity ranges from 100 to 500 tons per hour. Power requirements fall between 132 and 300 horsepower, depending on the model. Additionally, the adjustable CSS range of 4 to 40 mm provides high flexibility in controlling final product size, making the GP Series suitable for diverse mining and industrial crushing applications.

GP Series Cone Crusher Components

Main Shaft: Transfers crushing force and supports the crushing head

Mantle: The moving crushing surface

Concave: The fixed crushing liner

Eccentric Assembly: Generates eccentric motion for crushing

Gear and Pinion Shaft: Power transmission system

Lubrication System: Ensures smooth and reliable operation

Oil Radiator: Maintains optimal oil temperature during operation

Projects

GP Series Cone Crushers are widely used in:

Hard rock mining operations

Sand and aggregate production plants

Medium- to high-capacity crushing lines

Thanks to their adjustable settings and high throughput, these crushers are a reliable choice for professional crushing projects.

Kobesh Machine stands as a symbol of durability, high productivity, and secure industrial investment.

Contact Us

To receive tailored technical consultation, review high-capacity models, and select the most suitable solution aligned with the scale of your investment, please contact our executive team directly:

Sales Manager: +98 912 661 4519 — Alipour

R&D and Engineering Manager: +98 912 365 7790 — Alipour

Our specialists are ready to support you from technical evaluation to final equipment selection for large-scale and international projects.

Take control of crushing power—secure the future of your project.