Advanced Crushing Solutions by Kobesh Machine

With decades of continuous experience in the design and manufacturing of crushing equipment, kobesh machine is recognized as a leading manufacturer in the mining and asphalt industries.

Having successfully installed thousands of crushing machines worldwide, kobesh machine has built a strong reputation for reliability, performance, and engineering excellence across mining, road construction, and asphalt plant projects.

Product Overview

Application of Impact Crushers

Impact Crushers are designed for efficient crushing of a wide range of hard and semi-hard materials, including mountain rocks and river stones. These machines are capable of handling large feed sizes while delivering high reduction ratios, making them an ideal solution for secondary and tertiary crushing stages.

The end product produced by impact crushers is uniform, well-graded, and highly cubical aggregate, which fully meets the requirements of high-quality concrete production and industrial asphalt plants. Their ability to shape aggregates makes impact crushers a preferred choice in applications where product quality and shape are critical.

Available Configurations

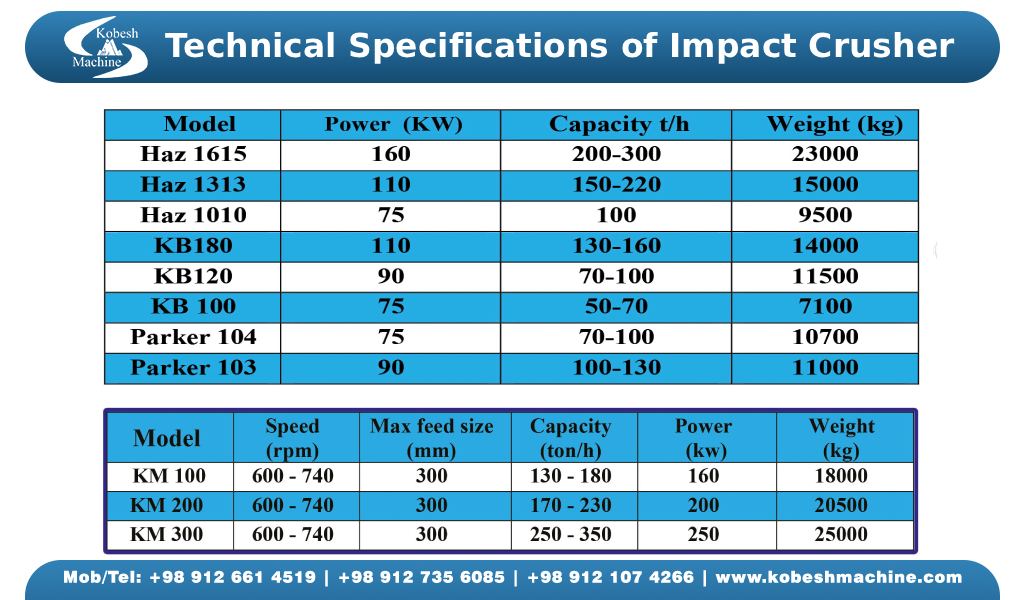

Impact crushers are available in various models and configurations to match different production capacities and project requirements—from medium-scale operations to high-capacity crushing lines in mining and large asphalt plants.

Key Features of Impact Crushers

All industrial Impact Crushers offer the following key advantages:

High reduction ratio compared to compression-type crushers

Production of cubical-shaped aggregates with excellent particle geometry

Accurate control over output size and gradation

Efficient crushing performance with optimized energy consumption

Long service life of wear parts made from high-quality, wear-resistant materials

Easy inspection and maintenance through access doors and hydraulic systems

Reliable and stable operation under continuous and heavy-duty working conditions

Impact Crusher

The Impact Crusher is a powerful machine designed for crushing soft to semi-hard and hard stones such as limestone, dolomite, basalt, and similar materials. By generating high-impact forces, this crusher produces a cubical-shaped and well-graded final product, making it ideal for concrete and asphalt production.

According to the catalog, this machine is mainly used as a secondary crusher in crushing and screening plants.

Structural Features

Heavy-duty steel body with robust industrial design

Large feed opening suitable for high feed sizes

Powerful rotor equipped with wear-resistant blow bars

Impact plates (anvils) with double-sided usage capability

Production of cubical-shaped final product suitable for concrete and asphalt

High reduction ratio and high production capacity

Automatic lubrication system (as shown in the catalog)

Low investment and operating costs

High operational safety

Operating Mechanism Description

The feed material enters the crushing chamber and is struck by a high-speed rotor rotating at 600 to 740 rpm (according to the KM series table).

The material is thrown against the impact plates (anvils), where further crushing occurs through repeated impacts.

The crushing chamber design and blow bar configuration ensure a cubical product shape and uniform gradation. The double-sided use of blow bars and impact plates significantly extends wear part life.

Construction Specifications

Crusher type: Impact Crusher

Installation type: Stationary

Applications: Sand, gravel, concrete, asphalt, and recycling

Power transmission system: Electric motor, pulleys, and belts

Adjustability: Adjustable impact plate gaps

Usage: Crushing and screening production lines

Component Descriptions

Based on the catalog images and reference codes, the main components include:

Blow Bars

The primary crushing elements mounted on the rotor, directly responsible for impacting and breaking the material.

Reference codes shown: 300, 303, 305, 1200Impact Plates / Anvils

Fixed plates inside the crushing chamber against which material is thrown after impact with the blow bars.

Reference codes: 1301, 1302, 1304Rotor Assembly

The central rotating assembly that carries the blow bars and generates the impact force.

Shown with reference code R130Support Blocks and Mounting Components

Structural and fastening components that secure the blow bars and impact plates.

Reference codes: 1201, 1202, 1203, 1801

Project Description

This Impact Crusher has been used in numerous crushing and screening projects and is recognized as a reliable solution due to its high capacity, consistent product quality, and low wear rates.

Typical project applications include:

Sand and aggregate production plants

Asphalt production facilities

Concrete batching plants

Limestone, basalt, and dolomite quarries

Concrete and construction waste recycling lines

Kobesh Machine stands as a symbol of durability, high productivity, and secure industrial investment.

Contact Us

To receive tailored technical consultation, review high-capacity models, and select the most suitable solution aligned with the scale of your investment, please contact our executive team directly:

Sales Manager: +98 912 661 4519 — Alipour

R&D and Engineering Manager: +98 912 365 7790 — Alipour

Our specialists are ready to support you from technical evaluation to final equipment selection for large-scale and international projects.

Take control of crushing power—secure the future of your project.