Reversible Impact Crusher

Advanced Crushing Solutions by Kobesh Machine

With decades of continuous experience in the design and manufacturing of crushing equipment, kobesh machine is recognized as a leading manufacturer in the mining and asphalt industries.

Having successfully installed thousands of crushing machines worldwide, kobesh machine has built a strong reputation for reliability, performance, and engineering excellence across mining, road construction, and asphalt plant projects.

Product Overview

Application of Impact Crushers

Impact Crushers are designed for efficient crushing of a wide range of hard and semi-hard materials, including mountain rocks and river stones. These machines are capable of handling large feed sizes while delivering high reduction ratios, making them an ideal solution for secondary and tertiary crushing stages.

The end product produced by impact crushers is uniform, well-graded, and highly cubical aggregate, which fully meets the requirements of high-quality concrete production and industrial asphalt plants. Their ability to shape aggregates makes impact crushers a preferred choice in applications where product quality and shape are critical.

Available Configurations

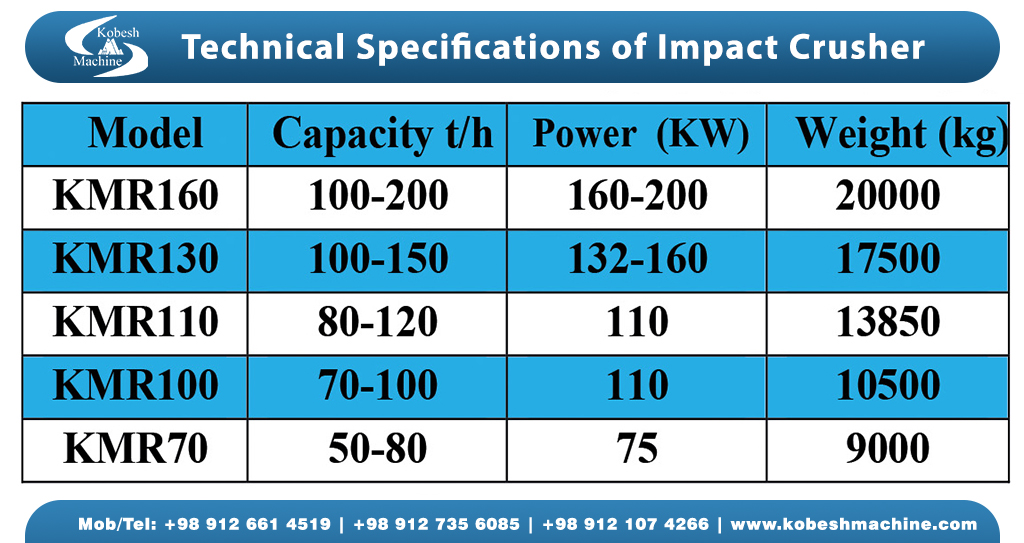

Impact crushers are available in various models and configurations to match different production capacities and project requirements—from medium-scale operations to high-capacity crushing lines in mining and large asphalt plants.

Key Features of Impact Crushers

All industrial Impact Crushers offer the following key advantages:

High reduction ratio compared to compression-type crushers

Production of cubical-shaped aggregates with excellent particle geometry

Accurate control over output size and gradation

Efficient crushing performance with optimized energy consumption

Long service life of wear parts made from high-quality, wear-resistant materials

Easy inspection and maintenance through access doors and hydraulic systems

Reliable and stable operation under continuous and heavy-duty working conditions

Reversible Impact Crusher

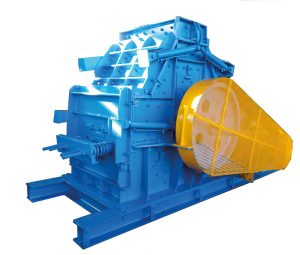

The Reversible Impact Crusher is one of the most widely used machines in sand and aggregate crushing lines. It is designed for crushing medium to hard stones and, thanks to its reversible rotor, increases component lifespan and overall efficiency. This crusher is capable of producing uniform particle sizes, typically ranging from zero up to approximately 10 mm. Reversible Impact Crusher

Structural Features

Reversible rotor design allowing the use of both edges of the impact components

Heavy-duty and robust body reinforced with thick steel plates

Use of replaceable blow bars and anvils

Strong steel base frame suitable for installation in stationary crushing plants

Protective safety guard for pulley and belt drive system (yellow cover)

Operating Mechanism Description

In this crusher, the feed material enters the crushing chamber through the inlet and is struck by the high-speed rotating rotor equipped with blow bars. The impact force throws the material toward the anvils, where further crushing occurs. Reversible Impact Crusher

The reversible rotation capability allows the rotor direction to be changed, enabling the use of the unused side of wear parts. This reduces downtime and extends the service life of critical components.

Construction Specifications

Main body: Heavy-duty industrial steel

Rotor: Dynamically balanced, reversible rotation

Power transmission system: Electric motor, pulley, and belt

Installation type: Stationary

Application: Stone crushing for standard sand production

Description of Machine Parts

Based on the component images shown in the catalog, the main parts include: Reversible Impact Crusher

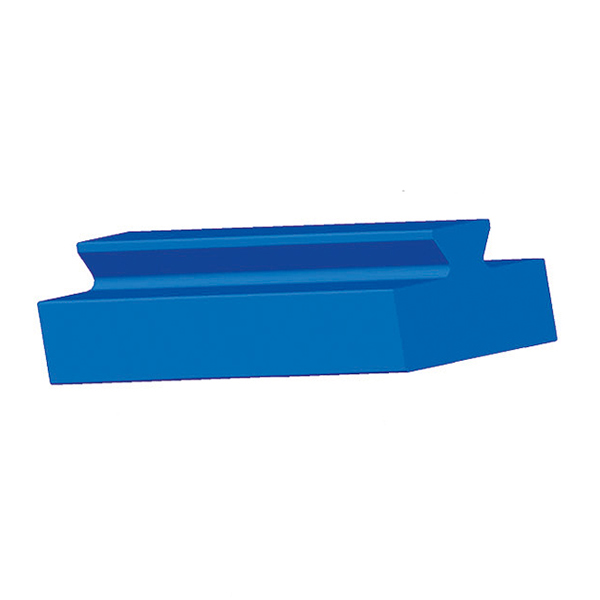

Blow Bars

The primary impact components responsible for crushing the material. They are designed to be replaceable.

(Shown in the catalog with codes 1103 and 1102)Anvils (Impact Plates)

Fixed plates inside the crushing chamber against which the material is impacted after being struck by the blow bars.

(Codes 1302 and 1303)Rotor

The central rotating assembly on which the blow bars are mounted, generating the required impact force.Pulley and Belt Safety Guard

A yellow protective cover that ensures operator safety and protects the power transmission components.Crusher Body and Base Frame

The main structural elements that support all components and provide stability during operation.

Projects and Applications

The Reversible Impact Crusher has been successfully used in numerous industrial and mining projects, particularly in sand and aggregate production plants. Its reliable performance, flexible capacity range, and robust construction make it suitable for a wide variety of crushing applications.

This crusher has been implemented in:

Sand and gravel production plants for producing uniform and high-quality aggregates

Quarry operations for crushing medium to hard stones

Stationary crushing lines in mining and mineral processing projects

Infrastructure and construction material plants supplying aggregates for roads, concrete, and asphalt

Industrial processing facilities requiring consistent output size and stable operation

In these projects, the reversible rotor design has played a key role in reducing downtime, optimizing wear part usage, and ensuring continuous operation. The machine’s heavy-duty structure and stable performance have made it a dependable solution for long-term industrial use.

Kobesh Machine stands as a symbol of durability, high productivity, and secure industrial investment.

Contact Us

To receive tailored technical consultation, review high-capacity models, and select the most suitable solution aligned with the scale of your investment, please contact our executive team directly:

Sales Manager: +98 912 661 4519 — Alipour

R&D and Engineering Manager: +98 912 365 7790 — Alipour

Our specialists are ready to support you from technical evaluation to final equipment selection for large-scale and international projects.

Take control of crushing power—secure the future of your project.