Advanced Crushing Solutions by Kobesh Machine

With decades of continuous experience in the design and manufacturing of crushing equipment, kobesh machine is recognized as a leading manufacturer in the mining and asphalt industries.

Having successfully installed thousands of crushing machines worldwide, kobesh machine has built a strong reputation for reliability, performance, and engineering excellence across mining, road construction, and asphalt plant projects.

General Introduction of Cone Crusher

The Cone Crusher is one of the main pieces of equipment used in crushing lines for mining, sand and aggregate production, and mineral processing industries. This machine crushes stones by applying compressive force between the mantle and the concave, using the rotary motion of the main shaft to produce uniform and controlled particle sizes.

Applications

Secondary and tertiary crushing in mining operations

Aggregate and construction material production

Sand and gravel crushing lines

Crushing of hard and semi-hard rocks

Types of Cone Crushers

Based on the catalog images, the following cone crusher types are available:

🔹 Standard Cone Crusher

Suitable for conventional crushing applications

Classic mechanical design

Various models with fixed power rating (90 kW for 36-inch models)

🔹 Hydro Cone Crusher CH-CS

Equipped with a hydraulic system (Hydroset)

Fast and accurate setting adjustment

Higher safety and reduced downtime

Designed for heavy-duty industrial applications

🔹 GP Series Cone Crusher

Cone crusher design focused on high-capacity production

Suitable for high-tonnage crushing lines

Stable and continuous performance

Common Features of All Models

The following features are common across all cone crusher models shown in the catalog:

Heavy-duty vertical main shaft

Wear-resistant mantle and concave liners

Dust sealing system (Dust Seal Ring)

Industrial-grade bearings and bushings

Designed for continuous operation in crushing lines

High-capacity output with uniform product size

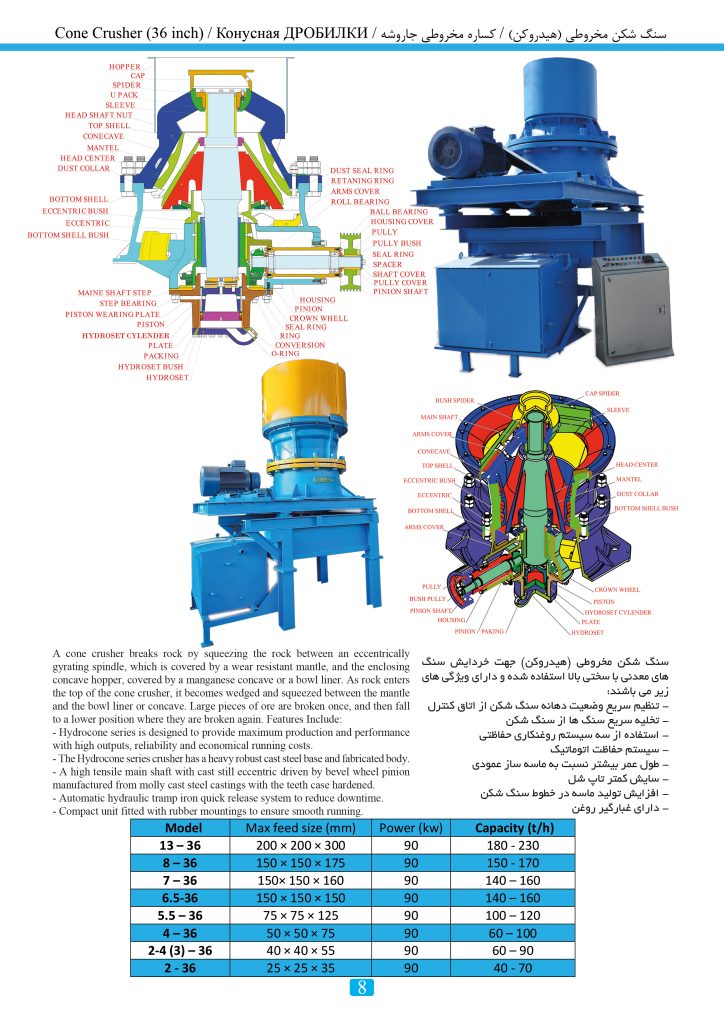

36-inch Cone Crusher

The 36-inch Cone Crusher is a key piece of equipment used in secondary and tertiary crushing stages in aggregate production plants. Utilizing a compressive crushing mechanism, this machine is designed for crushing hard and semi-hard rocks and delivers a uniform, well-controlled product size, significantly improving the quality of the final aggregates.

Structural Features

Heavy-duty industrial design with a robust steel frame and body

Use of wear-resistant mantle and concave liners

Hydroset system for adjusting the discharge opening

Automatic hydraulic protection system against uncrushable materials

High-tensile-strength main shaft

Durable bearings and bushings ensuring stable operation

Low vibration and smooth running due to rubber-mounted base

Suitable for producing high-quality sand and aggregates

Operating Mechanism Description

In a cone crusher, crushing is achieved through compression between the mantle and the concave.

The main shaft operates eccentrically, causing the mantle to move closer to and away from the concave. As material enters from the top, it is crushed in multiple stages while moving downward until it reaches the desired size.

The Hydroset system allows fast and precise adjustment of the discharge opening, providing effective control over product gradation.

Construction Specifications

Crusher type: Cone Crusher

Size: 36 inch

Crushing method: Compression

Installation type: Stationary

Adjustment system: Hydraulic (Hydroset)

Application: Aggregate plants and crushing & screening lines

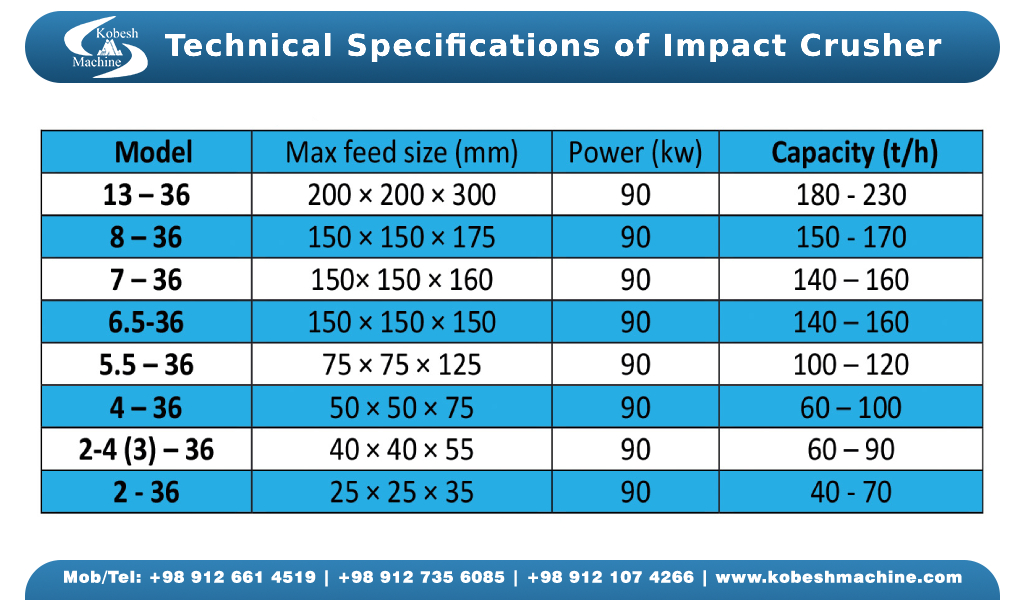

Technical Specification Overview and Performance Range

This technical specifications table demonstrates the high operational versatility of the 36-inch cone crusher and enables users to select the most suitable model based on the requirements of the crushing line. As shown in the table, despite a constant power rating of 90 kW across all models, the production capacity varies from 40 to 230 tons per hour, depending on the feed size and crusher setting. This indicates that by adjusting the feed opening and discharge gap, the crusher can be effectively used for a wide range of applications, from fine crushing to high-capacity operations. In addition, the maximum feed size ranges from 25 × 25 × 35 mm up to 200 × 200 × 300 mm, clearly highlighting the flexibility and adaptability of this cone crusher for various mining and industrial projects.

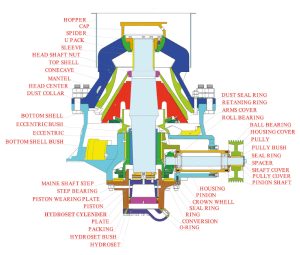

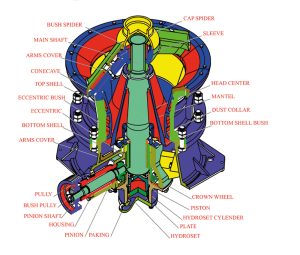

Component Descriptions

Based on the sectional and exploded views shown in the catalog, the main components include:

Mantle

The moving conical wear part responsible for the primary crushing action.Concave (Bowl Liner)

The fixed liner inside the crusher body against which material is compressed.Main Shaft

The central shaft that transmits eccentric motion to the mantle.Eccentric Bush

Creates the eccentric movement required for the crushing process.Hydroset Cylinder

Used for discharge opening adjustment and overload protection.Bearings and Bushings

Including step bearings, shell bushings, and roller bearings to reduce friction and increase service life.Dust Seal and Dust Collar System

Prevents dust and contaminants from entering internal components.

Project Description

The 36-inch cone crusher has been widely used in secondary and tertiary crushing projects in aggregate production plants.

With a capacity range of 40 to 230 tons per hour, a constant motor power of 90 kW, and adjustable discharge settings, this machine is well suited for projects requiring precise gradation and reliable long-term performance.

Typical applications include:

Hard rock quarries

Sand and aggregate production lines

Concrete and asphalt plants

Industrial grading and crushing lines

Kobesh Machine stands as a symbol of durability, high productivity, and secure industrial investment.

Contact Us

To receive tailored technical consultation, review high-capacity models, and select the most suitable solution aligned with the scale of your investment, please contact our executive team directly:

Sales Manager: +98 912 661 4519 — Alipour

R&D and Engineering Manager: +98 912 365 7790 — Alipour

Our specialists are ready to support you from technical evaluation to final equipment selection for large-scale and international projects.

Take control of crushing power—secure the future of your project.